Unleashing 3D Printing's Potential In Mold Manufacturing

Application Of 3D Printing In Injection Mold Manufacturing

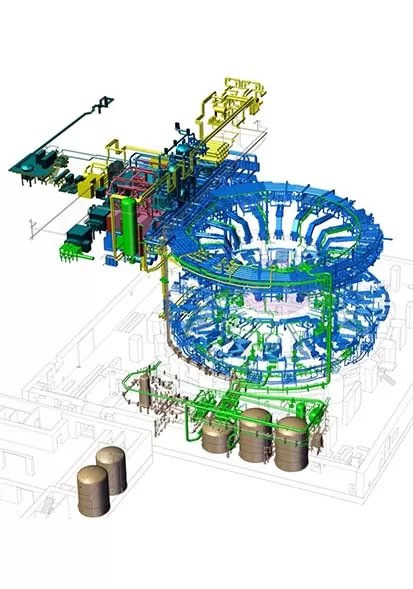

Advanced Application of Metal 3D Printing Solutions in Various Mold and Fixture Designs

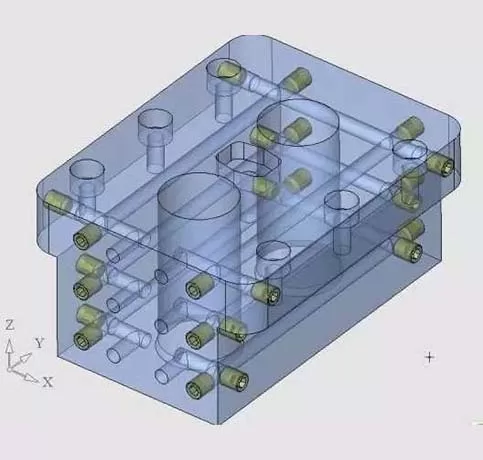

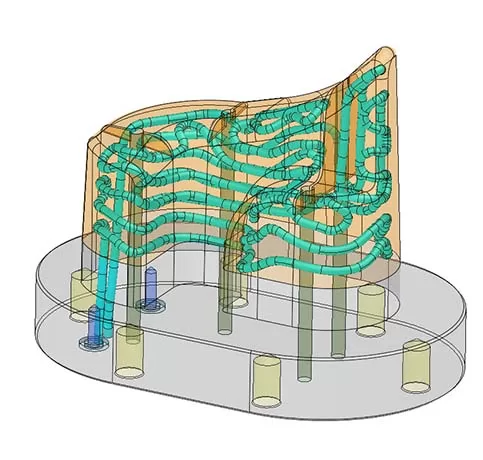

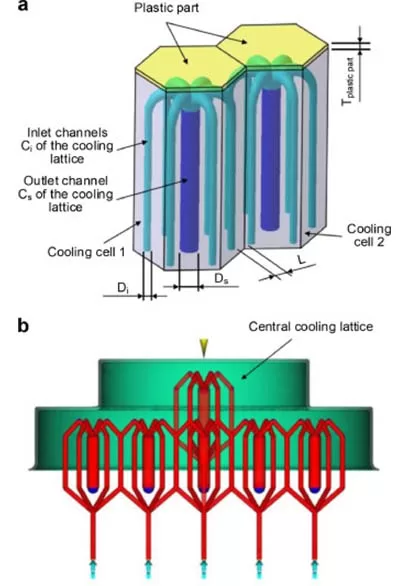

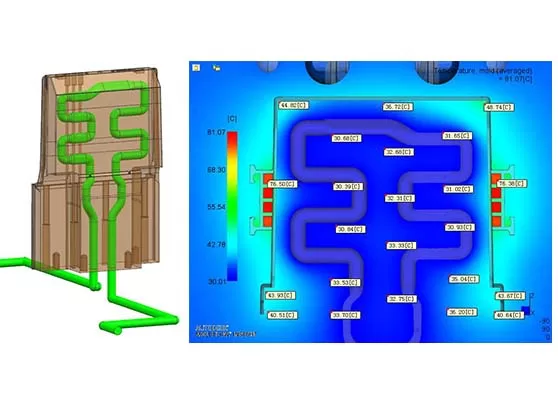

Conformal Cooling Channels

Optimized cooling channels that follow the mold's shape, ensuring efficient cooling and faster cycle times.

Venting Structure

Designed to release trapped air or gases during injection molding, improving mold filling and reducing defects.

Grafting Printing

Enables the use of different materials in a single 3D print, allowing for complex molds with varying material properties.

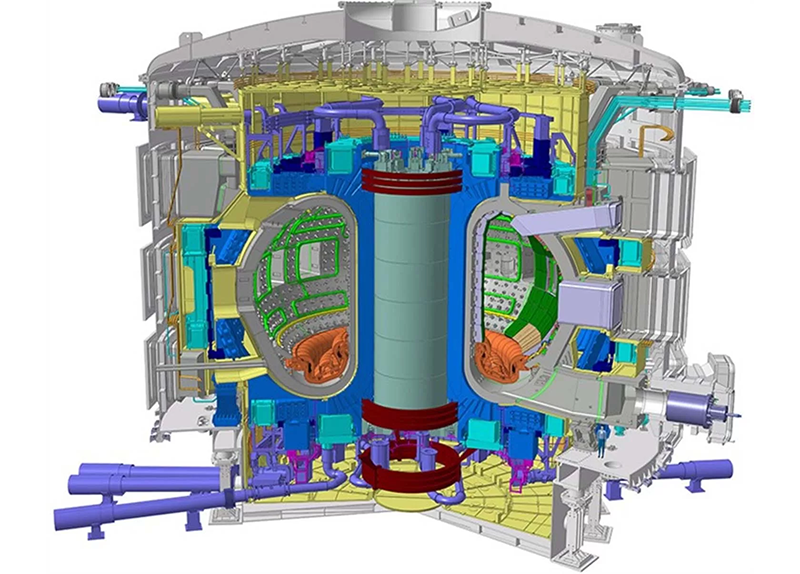

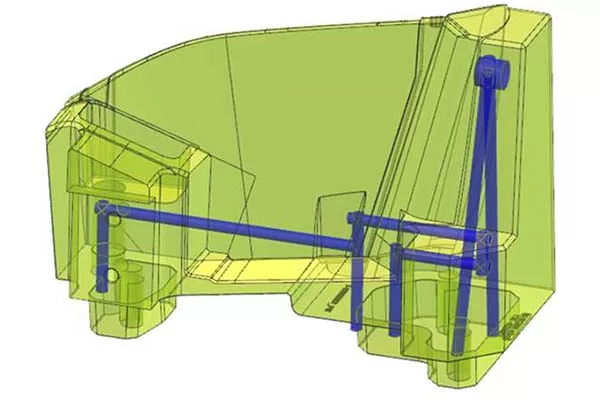

The mold cooling water system

The mold cooling water system is an internal pipeline system within the mold that circulates cooling water or other cooling media to control the mold temperature and improve production efficiency and product quality during the injection molding process.

The Mold Cooling Water System

The mold cooling water system is an internal pipeline system within the mold that circulates cooling water or other cooling media to control the mold temperature and improve production efficiency and product quality during the injection molding process.

Control Of Mold Temperature

Ensuring Consistent Quality and Dimensional Stability

Efficient Cooling Time

Optimizing Production Cycle and Efficiency

Uniform Cooling

Preventing Warping and Improving Part Quality

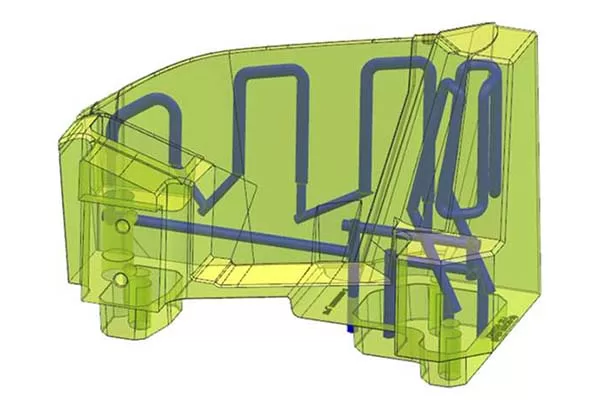

Conformal Cooling Channels

Conformal cooling channels, also known as conformal water channels or conformal cooling circuits, are a new type of mold cooling water system based on 3D printing technology. These channels are designed to closely follow the shape of the molded product, allowing for a precise fit and optimal cooling. Unlike traditional cooling channels that are limited to circular cross-sections, conformal cooling channels can have any desired cross-sectional shape, offering enhanced cooling performance and improved overall mold efficiency.

Traditional Water Channel Design

• Straight-line cooling channels that are positioned far or further away from the mold cavity.

• Requires additional fittings for water channel assembly.

• Contains more dead zones with poor cooling/heating efficiency.

• Requires cutting and assembling multiple pieces, leading to cumulative errors and shorter mold lifespan.

Conformal Water Channel Design

• Water channels designed to conform to the mold cavity surface, ensuring uniform proximity.

• Avoids right angles for smooth flow and improved efficiency.

• Allows for varying cross-sectional shapes of the water channels as needed.

• Enables the design of multiple cooling circuits to enhance heat dissipation uniformity.

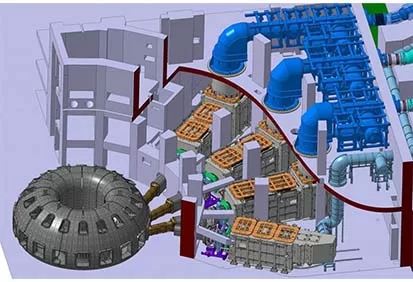

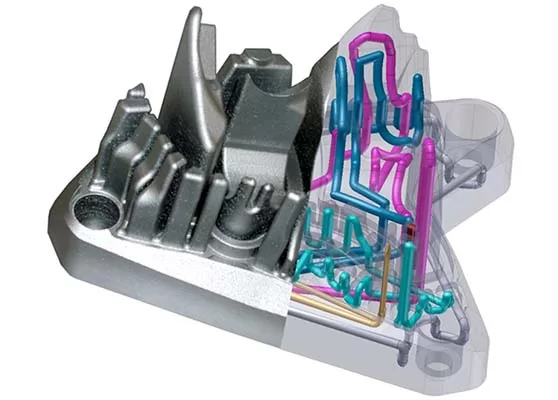

Enhancing Injection Molds with 3D Hybrid Printing

Advantages of Hybrid Printing

Cost reduction Shortened processing cycle

Hybrid Printing Methods

Same-material hybrid: Anco-X (printing) + Corrax (base) Different-material hybrid: UM300 (printing) + H13/8407/1.2344 (base)

Printing Process

Essential low-stress printing process that effectively reduces the risk of cracking. High-Gloss Technology

Injection Mold 3D Printing Process Steps

Our injection mold 3D printing process consists of the following steps: customer provides data and requirements, initial design and quotation, water channel design and analysis, contract signing and production arrangement, post-processing, quality inspection, and final delivery to the customer.

Data And Requirements Provided

The customer provides the necessary 3D printing data and requirements.

Design And Quotation

Initial design proposals and quotations are provided to the customer.

Water Channel Design And Analysis

Conducting design and analysis of the water channels for optimal performance.

Production Arrangement

Signing the contract and scheduling the production process.

Post-Processing And Quality Inspection

Performing post-processing steps, followed by thorough quality inspections.

Delivery To The Customer

Upon passing the quality inspection, the final product is delivered to the customer.

Introduction To 3D Printing Powder Materials For Molds

3D printing technology has revolutionized various industries, including mold making. The ability to create molds with intricate geometries and complex designs using 3D printing powder materials offers numerous advantages.

UM300 (1.2709)

Standard general-purpose mold steel material

- Extremely high strength and toughness

- Hardness up to 52-54 HRC

- Excellent polishing performance

- Good welding capability

- Good machinability

- Simple heat treatment process

- Not corrosion-resistant

Anco-X (Corrax)

Corrosion-resistant specialty material for molds with small-diameter water channels

- High-performance martensitic stainless steel

- Excellent corrosion resistance

- Hardness up to 48-50 HRC

- Excellent polishing performance

- Good hybrid printing capability

UH100 (H13)

Suitable for die-casting molds and injection molds (high glass fiber content)

- Extremely high resistance to thermal fatigue

- Hardness up to 52-54 HRC

- Excellent impact toughness and oxidation resistance

- Good machinability

- No need for heat treatment

- Not corrosion-resistant

- Suitable for both cold and hot molds

Advantages Of 3D Printed Molds

3D printed molds offer numerous advantages, including design freedom, reduced process steps, lightweighting, improved product quality, shortened production cycles, cost savings in injection molding, and increased economic benefits. Embracing 3D printing technology for mold production can revolutionize manufacturing processes and deliver significant benefits across various industries.

Design Freedom

Enables complex geometries and integrated functions in molds, expanding design possibilities.

Reduced Process Chain

Elimination of traditional machining steps saves time and costs.

Lightweight And Efficient

3D printed molds offer weight reduction and efficient use of material.

Improved Product Quality

Precise details and fine finishes result in better replication and reduced defects.

Shortened Production Cycle

Rapid design iterations and modifications reduce mold production time.

Lower Costs

3D printed molds eliminate expensive tooling and reduce injection molding costs.

Classic Case Studies Of 3D Printing In The Injection Mold Industry

These classic case studies highlight the significant impact of 3D printing in the injection mold industry, enabling faster production, improved design capabilities, and cost-effective customization.

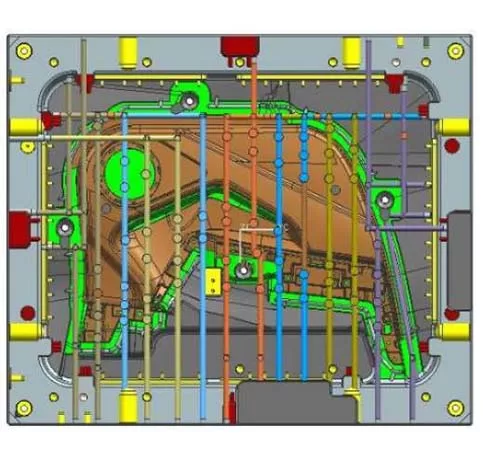

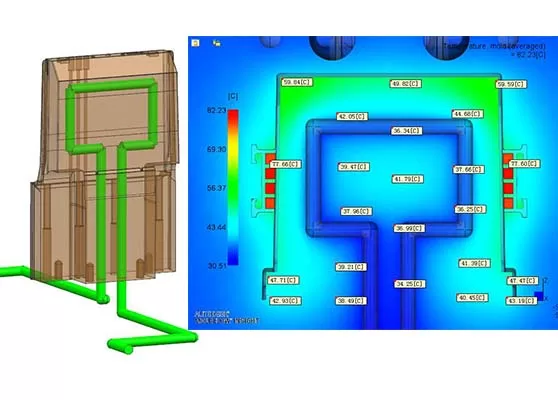

Replacement Of Traditional Mold Steel With 3D Printed Mold And Conformal Cooling Channels

The product's small dimensions in deep grooves make it challenging to incorporate traditional water channels, resulting in significant heat buildup.

Tooling Cooling Design

The product's small dimensions in deep grooves make it challenging to incorporate traditional water channels, resulting in significant heat buildup. The original mold insert utilized beryllium copper with traditional water channels. However, the limited hardness and strength of beryllium copper led to issues like cracking and wear. Therefore, alternative solutions, such as heat-dissipating steel or conformal cooling channels, are being explored.

Traditional Water Channels

Conformal Cooling Channels

© 2024 All Rights Reserved.