What is Overmolding?

Many of the products used daily are made possible by producers and suppliers of rubber and plastic. These substances are robust, adaptable, and capable of practically any shape required for various industrial purposes. Several varieties are also developed to withstand harsh environments to aid in completing even the most difficult tasks. In addition, through the use of overmolding, manufacturers are able to increase the effectiveness of rubber and other materials. This procedure allows industrial products to be made even stronger, more aesthetically pleasing, or with an additional purpose by using more than one layer of rubber or plastic.

Several different manufacturing and industrial sectors can use the overmolding technique. Overmolding is an injection molding technique that uses many materials to form a single object. Two or more layers of material can be molded together with this injection molding. Both rubber and plastic overmolding might benefit from the procedure. The first substance is typically referred to as the substrate substance, which may be partially or completely covered by subsequent substances (overmolded materials).

Initially employed to enhance the aesthetics of consumer items, injection overmolding is today fairly common. The technique has several uses and can even be applied to increase the operation of a product, such as increased chemical resistance, offering electrical insulation, creating a firmer, more durable grip, etc.

What is Overmolding

There are primarily two distinct types of overmolded product production processes.

Molding Soft Material Over Hard Material: The thermoplastic elastomer (TPE), a frequent component in multiple injection molding, is applied to substrate materials like acrylonitrile butadiene styrene (ABS). TPE-V, TPE-U, TPE-E, and TPE-A are the most frequently utilized TPEs. These "soft cladding" solutions offer higher insulation, chemical resistance, ergonomics, handling, and grip, superior aesthetics, and enhanced utility.

Hard Material Overmolding Hard Material: Hard plastic is often used in secondary overmolding applications- for instance, rigid molded plastic with a metal insert or rigid molded plastic transparent with opaque sections.

Industries that need to produce prototypes of different industrial machine parts quickly can benefit from overmolding. The method is especially useful when creating unique parts that combine rubber or plastic with other materials, such as metals.

There are numerous reasons for overmolding. One of the most typical is to increase a product's grip while maintaining its physical strength, like in the case of a power tool's handle or a surgical instrument's non-slip grip. TPU is a superior option over ABS in this situation. With overmolding, aesthetics and product branding are also easily accomplished. For example, a sports team might use two-piece overmolded mouth guards in the team's colors for its players, and a well-known tractor manufacturer might decorate its riding lawn mowers with green and yellow overmolded cowlings.

One of the most well-liked and cutting-edge rapid tooling techniques is overmolding, which offers tremendous potential in reduced production costs and cycle times, and new design options for manufacturing products. It has been extensively utilized in mobile phones, pen manufacturing, autos, home appliances, hand tools, and commodities, among other things, due to the various design advantages of overmolding goods.

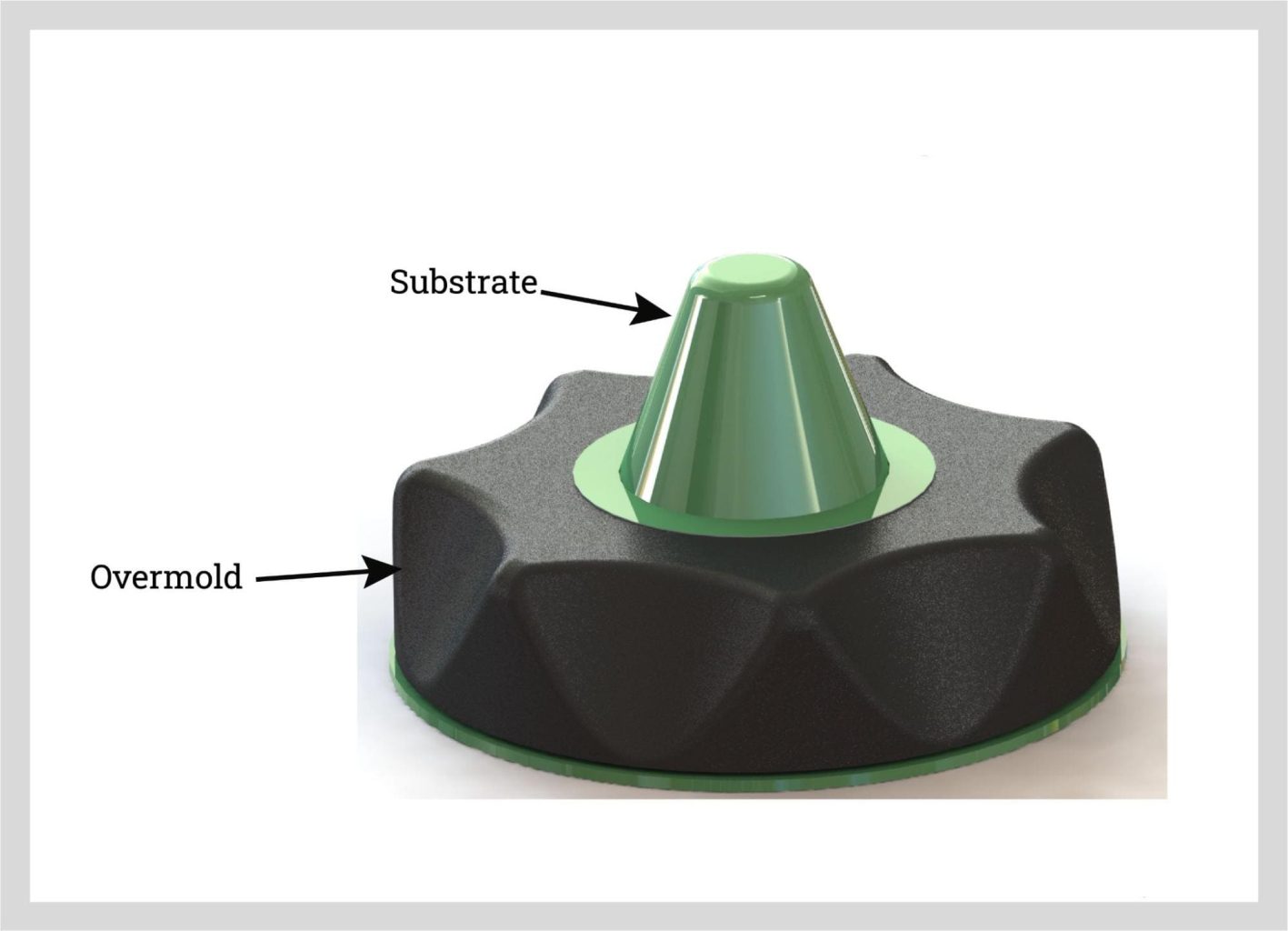

Overmolded Bowl

How is Overmolding Performed?

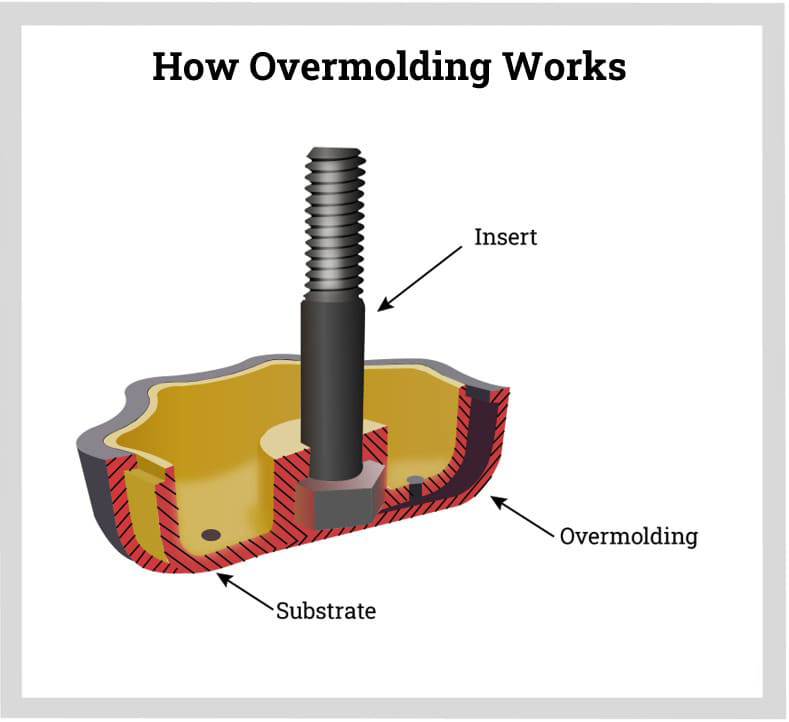

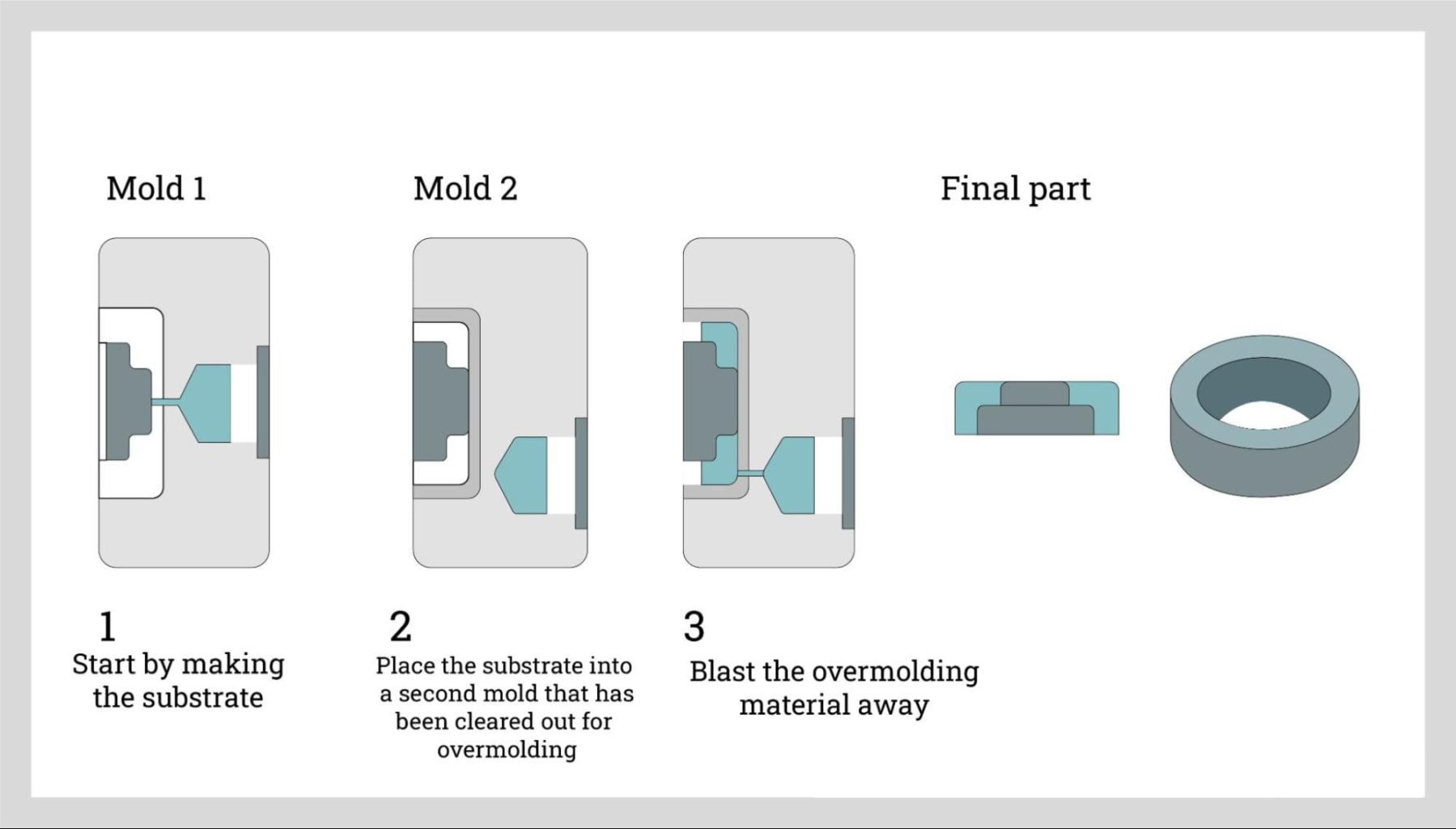

A machine part or component made by fusing two or more materials results from the overmolding process. Either the same materials or alternative materials can be used. There are no limits to the material combinations. Understanding the two halves of the process is necessary to understand better how it operates. Every overmolding project is composed of two components. The substrate is the first step in the process, and the overmolding is the second.

The fundamental substance is the substrate. Any of a huge range of materials could be used. The secondary substance is the overmold. One aims to "mold over" the substrate using this substance. In some circumstances, other manufacturers may use two or more overmolds in their manufacturing process. The number of overmolds will vary depending on the final product intended and the manufacturer's creativity.

How Overmolding Works

Guidelines for Overmolding

A fantastic technique to enhance a product's physical qualities or aesthetic appeal is overmolding it. With a few more restrictions, overmolding follows the same guidelines as conventional injection molding processes:

Both sections must retain proper draft angles, uniform wall thickness, and clean transition lines.

The overmolding material's melting temperature should be lower than the substrate, and its thickness should be less than or equal to that of the substrate below it.

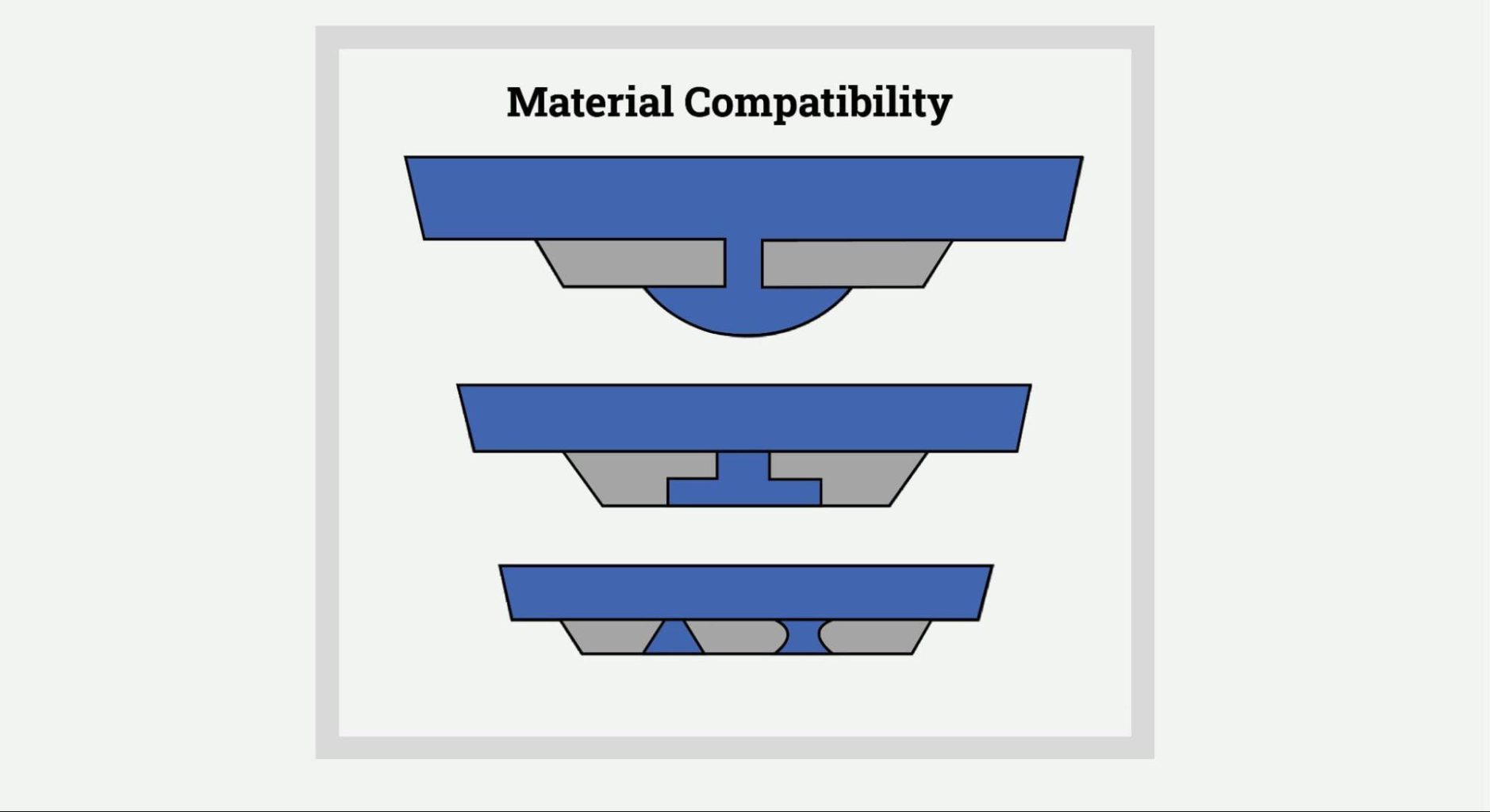

Keep going if chemical bonding is not feasible. Instead, mechanical interlocks should be employed when possible because they are a terrific method to "keep it all together."

The substrate workpiece's texture may promote adherence. The overmolded item’s surface should be level with or just below any neighboring substrate surfaces. Texturing the overmolded part may offer a stronger grip and a more appealing surface.

Considerations in Overmolding

To produce the best products, overmolding manufacturers take various factors into account during the manufacturing process. If the product's end customers wish to choose the ideal overmolded part for their application, they also need to consider these factors. Below are some factors to take into account during over-molding.

Bonding

The overlay will break before separating from the substrate in a perfectly overmolded item and may even take some of the underlying material. The formation of a strong chemical link is only sometimes possible or even essential, though. For example, consider a molded electronics housing cover with a soft sealing gasket overmolded. The gasket has nowhere to go once the cover is fixed in place. All that is required is sufficient binding to secure the gasket to the substrate and prevent it from coming loose or disappearing during assembly. Since it eliminates the requirement for a stamped paper or rubber gasket that must be manually glued in place, this is a great application for overmolding.

Getting the ingredients to fuse is the aim of any overmolding process. Some materials could need help joining together. Two materials having trouble bonding could be "forced" to come together. To facilitate the procedure, indentations or undercuts can be made in one of the materials.

Engineers typically advise using a mechanical interlock in place of or in addition to a chemical bond. The substrate component can be given an undercut, or a sequence of reverse-tapered or counterbored holes can be drilled into the part to allow the overmolded material to flow, guaranteeing a no-fail mechanism in all but the most demanding situations to accomplish this.

Rubber to Metal Bonding

Bonding overmolded parts techniques:

Physical approach: Buckle design, surface rolling, surface tapping, followed by using a second material to produce a package that is directly molded (covering). The physical joint has great adhesion on the inside, while it has limited adhesion outside, which is a feature of material bonding solely via this method.

Chemical method: This combines two materials using their molecular affinities and chemical bonds to create a single part, two parts, or more. Realizing the connection between the two materials is more dependable and flexible, even though the physical clasp and bonding methods are frequently combined in actual applications. The mutual solubility, penetration, entanglement, and penetration of molecules or molecular chains make up this powerful chemical relationship.

Temperature

While some materials work well for flexible applications, they cannot withstand high temperatures. Therefore, the majority of overmolding techniques use some heat. This consideration is particularly accurate when discussing injection molding. Overmolded part manufacturers must use materials that can withstand high temperatures without losing their original properties. This concern holds for both the substrate material and the overmolded substance.

Friction

Each material used in the overmolding process has a different level of friction. How easily two materials can move against one another is determined by friction. Any substance's "coefficient of friction" determines how much or how little friction it produces. The ability to successfully bond materials together depends heavily on a material's coefficient of friction and surface texture. Two materials will attach more readily the more surface texture and friction there is.

Thickness

Another excellent performance indicator is material thickness. The overmolding procedure is occasionally utilized in applications for dampening sound or vibration. Thick materials are needed for these applications to ensure that the final product is effective. The vibration will be well-absorbed by thicker material. It will feel soft as well. Thicker materials will feel stiffer and function less effectively at dampening vibration or sound.

Materials Used

Which substances are most effective for overmolding? Well, there are countless possible combinations. It all depends on the end goal. Different materials have various advantages and qualities. Some are better suited for harsh situations than others, while others are great for strength and flexibility. Intelligent manufacturers use a general evaluation technique for all materials when choosing overmolding materials. There is a steady development of new materials used for overmolding. Instead of analyzing each piece of content separately, it helps to have a consistent evaluation process for comparison.

Material Compatibility

Hardness

The materials involved may suffer during the overmolding process. Occasionally, a material sturdy enough to resist indentation during the overmolding process is required. End users must assess if the material they are using will also bend. This trait is significant because the ultimate product's grip could be impacted if the material bends. The two materials might only stay together if the final product has a good grip.

Leading Overmolding Companies

LTM Plastics

MSI Mold

GSH Industries, Inc.

Britech Industries

Hi-Rel Plastics & Molding

Molded Devices, Inc.

Mouse Over Company Names to see their previews

Chapter Three: Types of Overmolding and Overmolding Processes

Different overmolding techniques are employed by manufacturers, depending on the materials and desired overmolding methods. Therefore, these categories will cover the majority of overmolding initiatives carried out in the manufacturing sector.

Four Types for Overmolding

It is important to remember that some materials cannot be overmolded. There are four types of overmolding.

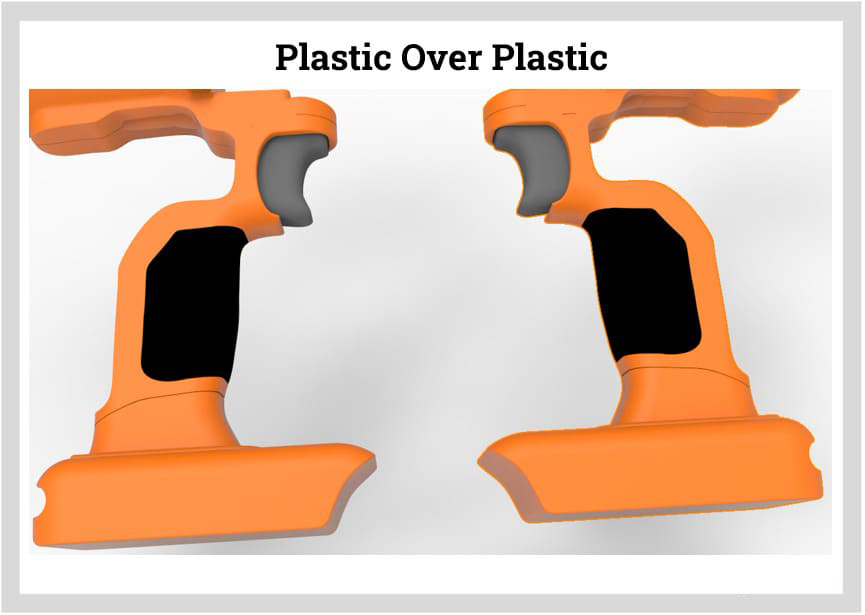

Plastic Over Plastic: Plastic is used for both the substrate and the plastic poured on top of it. The melting point of the plastic component's material should be the same or close to it.

Plastic Over Metal: Metal serves as the substrate. A metal component—cast, forged, or CNC-machined—is first placed in the mold before the plastic is molded over it. Metal inserts can also be molded within plastic components.

Elastomer Over Plastic: Hard plastic should be the base material. Rubber and polyurethane are examples of soft materials that could be elastomers.

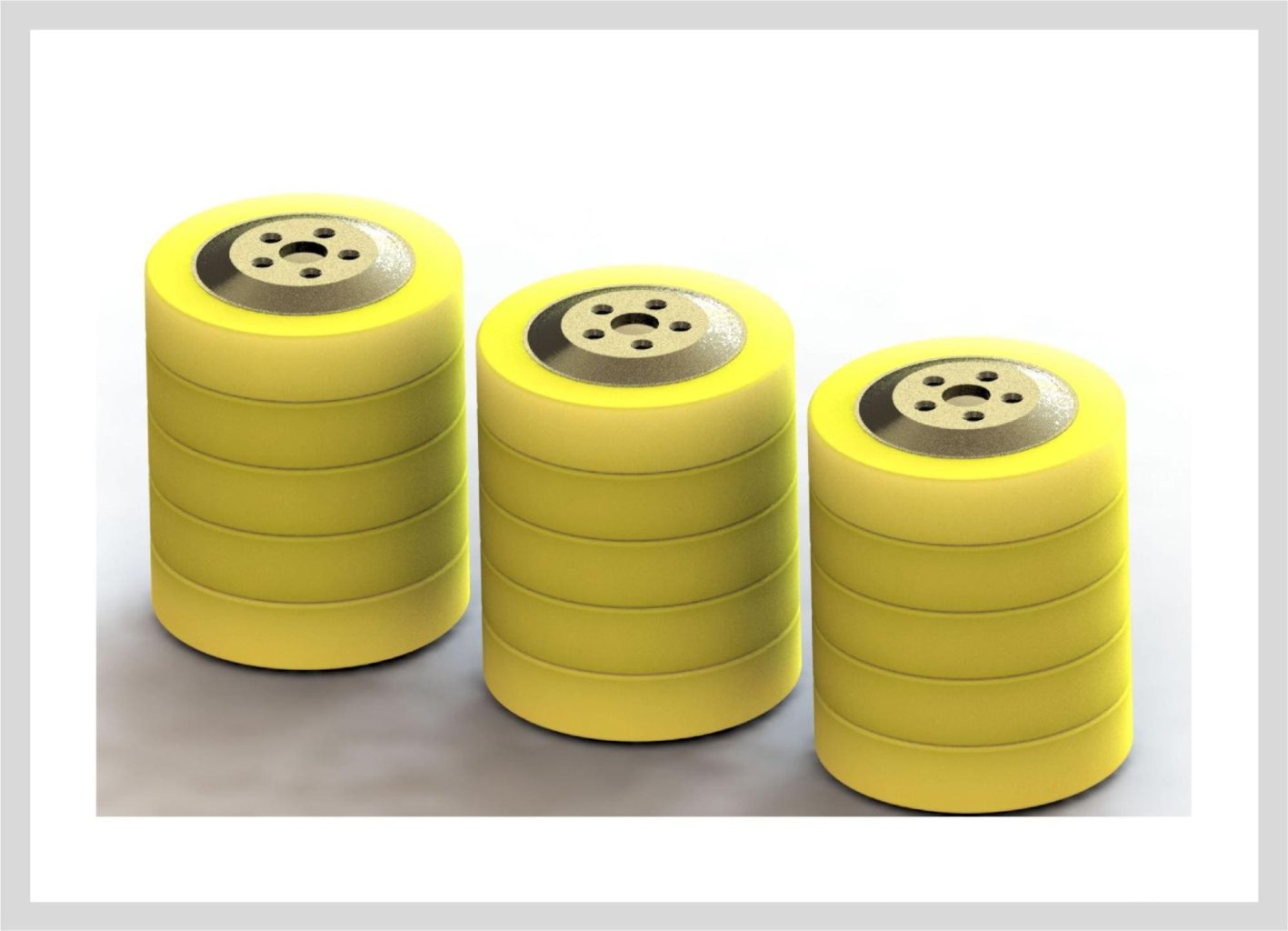

Elastomer Over Metal: Metal serves as the substrate. A CNC-machined, casted, or forged metal component is placed into the mold before the elastomer is formed over the handle.

Overmolding Processes

In addition to there being various types of overmolding, there are several manufacturing processes that may be used to perform this function.

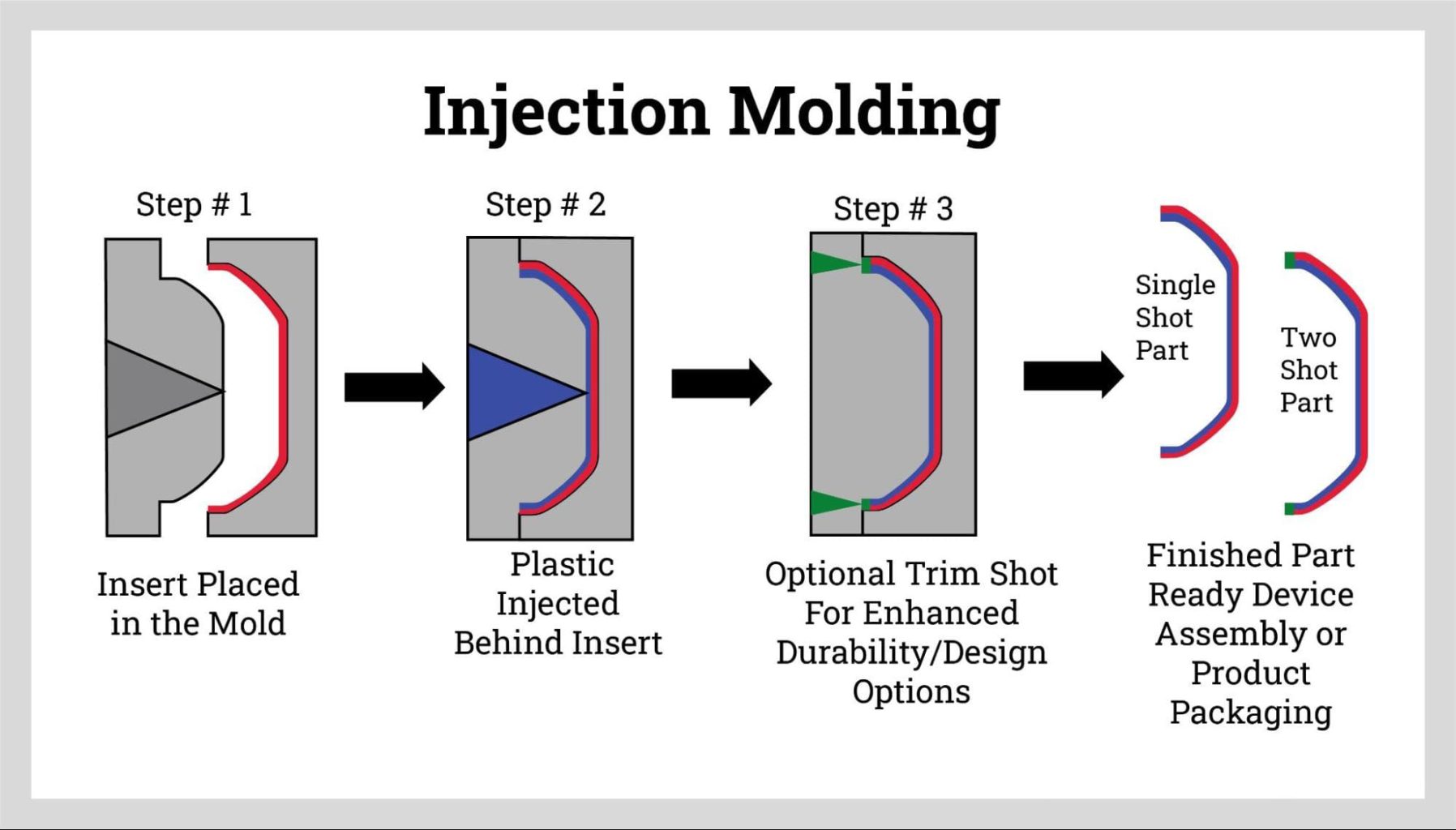

Injection Overmolding

Dual-injection molding is one of the common styles of overmolding. The most expensive and challenging sort of overmolding to manage is this one. The maker would not inject an overmold onto an existing substrate, which distinguishes this technique from others. In this procedure, producers inject the substrate and the overmold into the same mold. Given that both materials must be compatible for this to function, this adds another element to the process. One of its main advantages is that all materials are liquid during the injection molding process. This quality makes it possible for the best possible molding and material adherence.

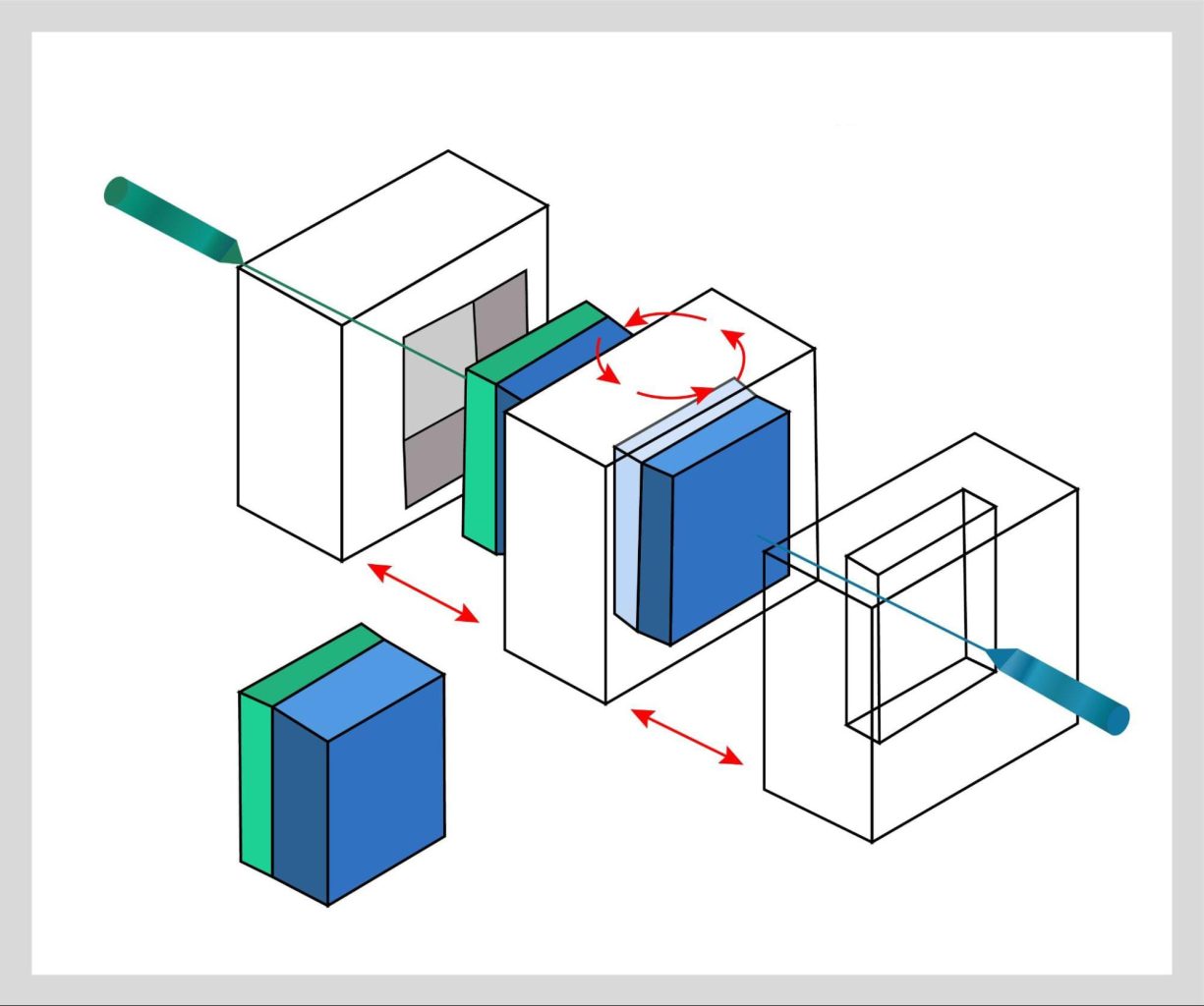

2K Overmolding

Two steps are involved in the 2K (two-color) overmolding process, which involves turning a material injection into products on a 2K injection molding machine and then switching to another note in the plastic tube of the matching mold cavity on the 2K machine. The component is utilized as inserts, which are then injected onto another material to create items that incorporate two materials. Two different material products can simultaneously be produced when using a twin cylinder (or double mold) cavity injection molding machine. The manufactured item is currently being used as inserts for other products.

The first shot of hard plastic injection molding is still hot when it enters the second cavity of the 2K injection molding machine, which is one benefit of 2K overmolding. However, due to the lack of moisture absorption during the transfer process, the surface may easily be ablated by the high-temperature TPE melt to create an incredibly thin layer. There is also no effect of water vapor adsorption.

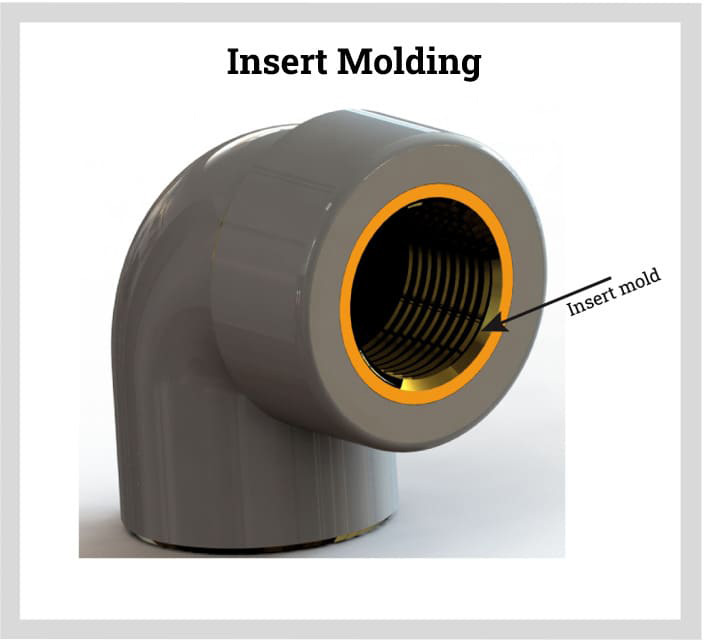

Insert Molding

When working with plastic overmolding, insert molding is the most common technique. This technique includes both flexible elastomers and strong, rigid plastics. Because the insert molding technique is simpler to complete, it is the optimal type of overmolding for these materials. It follows that of the overmolding procedures, it is also the most cost-effective. The hard plastic components must first be divided into tools before performing an insert mold. The softer materials are then inserted after that. These flexible elastomers help the two materials adhere to one another. The adhesion bonding procedure might be challenging. The soft elastomers must achieve the correct temperature for the adhesion bond to function effectively. Heating the elastomer also heats the surface of the hard plastic, allowing the two components to connect.

Two-Shot Overmolding

Another process is two-shot overmolding, which involves creating a material portion on a molding machine and inserting the material part into a different mold before injecting a second material. Two injection molding machines must be simultaneously used when performing the two-shot overmolding process. The hard section will be injected first by manufacturers. This substance is always in a semi-solid or gel form. When injected, it will adopt the form of the elastomeric mold already set up in the apparatus.

The item is initially created as a stiff item for inserting molding and placed within the mold chamber. The finished product is then produced using thermoplastic elastomer (TPE) to inject additional molding into this component. Insert molding can be done using standard injection molding machinery. Manual or motorized arms can be used to place rigid components. Typically, this is the only application for coated metal parts. One mold is needed for the substrate, and the other is for the finished, over-molded product in the two-shot process. Additionally, a person is required to tend the machine, load substrate components, and unload finished goods, a procedure termed "pick-and-place" rather than molding.

The two-shot overmolding method can give producers a reliable mechanical bond. As a result, numerous manufacturing businesses benefit from increased strength and stability.

Urethane Casting

Many plastic parts and products are manufactured using the industrial-strength resin known as urethane. It's a fantastic material since it can be tailored to fit hard or supple, flexible items. Urethane is poured into a mold during the procedure, and the mold is let to dry. The material cures while sitting, giving the producer its finished product. Many commercial producers favor urethane casting as an alternative to molding. The reason is that urethane casting is a terrific approach to creating models and parts that are both affordable and of good quality. It's also a fantastic technique for more intricate designs.

Manufacturers will utilize a silicone mold to start the procedure. A CNC machine or 3D printer is typically used to create this mold. Once the mold has been made, the silicone is next poured into it. As the silicone cools, it will relax and assume the shape of the mold. Next, the urethane will be delivered as two different liquids that must be combined in a 1:1 ratio. After mixing them, the chemical reaction will begin. The conversion of urethane from a liquid to a solid occurs due to this chemical reaction known as curing.

The urethane should typically cure for an hour or so. But it makes sense to review the urethane's instructions before using it. The curing process for some materials could take longer. The new part or model can be removed from the mold after the urethane has dried and hardened. With a specific silicone mold, manufacturers can use the same casting technique up to twenty times.

Applications of Overmolding

Cookware

Food safety is essential when using plastic to make items like cookware, food containers, and kitchen utensils. Given this, it should be no surprise that overmolding should be a crucial process for producing cookware parts and components.

Overmolding is used in cookware for a variety of purposes, such as spatula handles, pot covers, stove trims, knives, cutting boards, and more. These products use high-grade polymers that won't compromise the flavor or freshness of food, boosting consumer safety.

As previously indicated, one benefit of overmolding is that it makes items easier to hold, use, and keep clean. In addition, overmolding uses components to increase a product's chemical resistance, vibration dampening, sound insulation, and many other properties.

It is no surprise that a variety of home objects, including toothbrushes, culinary utensils, portable electric fans, mirrors, pens, multi-port chargers, shampoo bottles, reusable food containers, and the like, are created from overmolding. Even when it just entails making the products simpler to clean and operate, lessening wear and tear, and extending the shelf life, overmolded products are made to enhance the end-quality users of life.

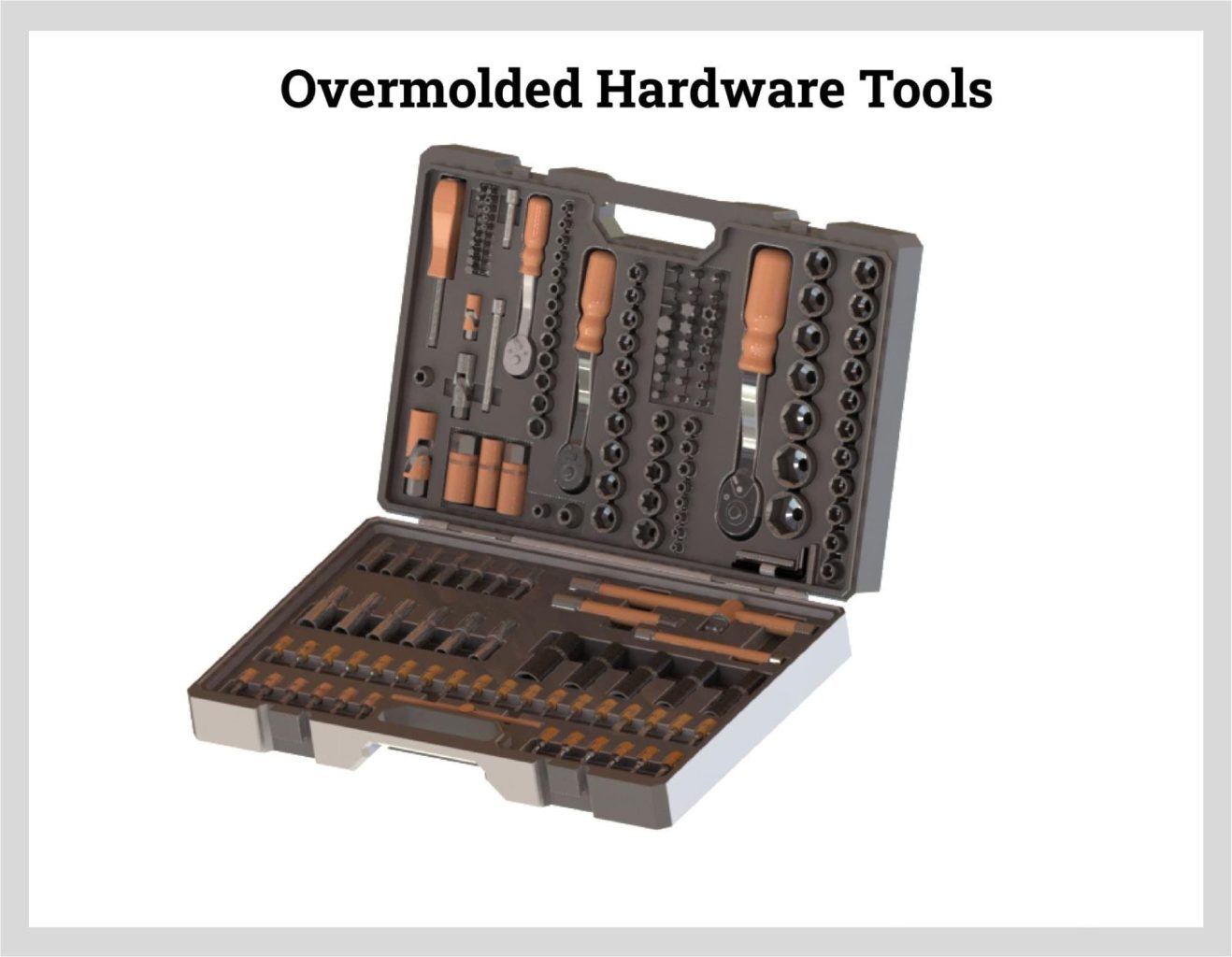

Hardware Tools

Various hardware tools provide a wonderful illustration of overmolding. These might include blades, pocket knives, pliers, wrenches, hammers, tape measures, and other similar tools.

The primary machining components for these materials are typically composed of steel, which can be used for cutting, bending, drawing, punching, and other sorts of fabricating processes. However, the end-user must first be able to handle these tools safely and ergonomically before the steel component is usable, and this is where overmolding comes in.

Using these common tools might be challenging without overmolded handles, whether you're fixing automotive components or working on a home improvement project. The substrate for the overmolding process can be made of several polymers. After that, a rubberized plastic will be added to this substrate in a two-step injection molding procedure to complete the handle and enhance the user's grip on the instrument.

Medical Equipment

Precision and product safety are important factors in the medical sector. For example, when employing various kinds of surgical tools, professionals like doctors, surgeons, and nurses should be able to rely on safe plastic material. Additionally, this equipment should be sterile and simple to clean to avoid infection.

Overmolding has also been extensively utilized in this business. Overmolding is used to produce various medical goods, including housing for equipment and surgical instruments, to produce a completed part that facilitates use. Syringes, patient monitors, needles, catheters, dilators, soft-touch buttons, and many more are a few examples.

Auto Trims

The pieces located in various regions of the automobiles, such as the door edge, side body, fender, bumper, wheel, and other areas in the interior, are referred to as car trims or car moldings. Car trims have certain practical advantages, particularly in lowering the vehicle's weight, although they are frequently fitted for their visual appeal. Overmolding has various functional benefits, as was covered in the sections before this one. Beyond that, overmolding provides a flexible plastic production technology because of its numerous inventive applications. The customer's desired colors can be used to create custom or pre-set automotive trims.

To be molded with additional materials, such as steel, chromium, or any metal plating, these overmolded trims can also go through a different procedure known as insert molding.

Chapter Five: Benefits of Overmolding

There are several advantages of the overmolding technique that can be seen in various applications, including electrical assembly and domestic purposes.

Boost IP Rating

The overmolding technique forms a material bond around PCBs, wires/cables, and connectors to shield electrical components from dirt, dust, and debris. An electrical assembly that has been overmolded can meet IP67, IP68, and IP69K specifications.

Greater Efficiency

The long-term performance will be improved by combining two materials to create a finished product. Products might survive longer than they would if only one material were used.

Additionally, overmolded products will perform better at absorbing shock and vibration. Finally, overmolding can even help increase a product's chemical resistance.

TPE is an illustration of this kind of substance. TPE can aid in producing a non-grip property after the overmolding process. When necessary, it can also serve as an environmental barrier.

Improved Aesthetics

To enhance the designs of various tools, parts, and models, overmolding might be useful. Because the materials can be various colors, it is simple to make overmolded materials look appealing.

Overmolding is the best procedure for designers to make a single plastic item with various colors or surface treatments. For example, one part with perfectly integrated colors and finishes can be created by overmolding various colored or textured components with one another. To make one automotive lens, for instance, a clear resin part might be overmolded with a black resin part. Metal inserts overmolded into plastic also appear nicer than inserts manually placed within the plastic parts.

Overmolding can play a key role in improving many products’ comfort and appearance. Tools are one instance of this. For example, the overmolding procedure can add comfortable rubber grips to hammers, saws, and other equipment.

Enhanced Stress Relief

Electrical connections can become stressed if the electrical assembly is regularly plugged in and out or if it is utilized in situations where the cable is moved around a lot. Compared to more conventional shields like heat shrink, potting, and backshell connectors, an overmolded connection is far more resilient. The overmolding may also be flexible, which further lessens strain by dispersing the tension over a wider area rather than concentrating it entirely at one particular location.

Shock and Vibration Protection

A mechanical breakdown can result from shock and vibration if electrical components are not adequately shielded. It's essential to stop components from moving around within the assembly to guarantee the connection stays strong in conditions with significant vibration or shock. Overmolding is the best method for preventing fatigue and other damage since it fills in any gaps surrounding internal components. Hence, there are no air gaps that could cause components to shift.

Cost-Effective Molds

Making an aluminum piece into the precise shape required to safeguard an electrical connection or PCB might serve as the basis for a mold for an electrical assembly. An overmolding mold comprises a top and a bottom piece that fit together around the intended component. A mold can be stored and used again after it has been made.

Improved Assembly

Because the plastic placed over the substrate during the overmolding process is melted and then cured on the substrate, it creates a more solid assembly, and the two or more components that are molded together fit better than two components that are manufactured separately and then combined.

Cost-Effective Parts

Due to how beneficial overmolding is, many people believe it to be expensive. However, contrary to popular belief, this is untrue. One thing that makes overmolding such an appealing technique in the first place is its cost-effectiveness.

Manufacturers can construct a superior electrical assembly using less expensive parts because overmolding forms a sturdy, weathertight barrier around electrical components. Unsealed connectors, for instance, are less expensive than sealed connectors. They can employ unsealed connectors if they know during the design process that they will be using overmolding to safeguard electrical connections. The seal created by the overmolding will typically be stronger than the seal created by a sealed connector, and the same is true for terminals and PCBs. Using the most robust materials is necessary so one can examine how they will hold up in the environment in which they will be utilized.

It is possible to get high-quality outcomes while minimizing manufacturing costs by overmolding the materials. In addition, the comparatively straightforward nature of this method makes it useful in fields that demand quick production.

Automated, Rapid Process

Construction of the mold by manufacturers is delegated to the machine, which will then complete the overmolding task. Machines can connect two overmold connections in 30 seconds, which is substantially quicker than applying other connection protection techniques. Throughput goes up, and labor costs go down as a result.

More Approachable

It is more comfortable for end users to employ elastomers like rubber or polyurethane over hard plastic or metal items. The texture of hard plastic and metal parts can be softened by adding a soft coating, making them more user-friendly. On the other hand, hard plastic and metal pieces are not very pleasant to the human hand.

Customization

The degree of customization that can be used is the least evident benefit of overmolding cable assemblies. While it is feasible to mold already existing assemblies over, producers can also design a singular product that precisely satisfies the needs of a given application.