Manufacture Of Screws And Tubes

Profession R & D Design ,Production Technology,Product Control And Technical Service Team, Advanced Processing Equipment At Home And Abroad

ISO 9001:2015 IATF16949:2016

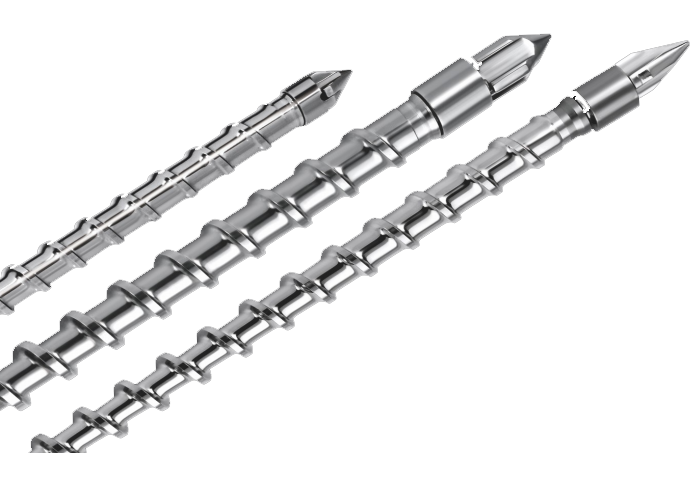

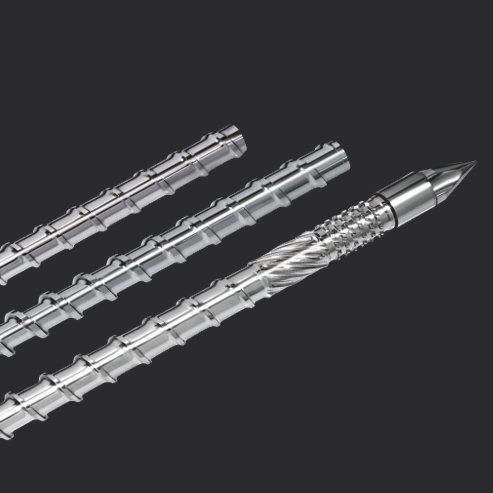

Optical special screw

Imported alloy tool steel / high-speed steel as raw materials, through the overall vacuum quenching, secondary tempering heat treatment, combined with "full hardness without school point" processing technology overall hardness HRC: 60 ~ 63 degrees. Make its steel play a strong wear resistance...

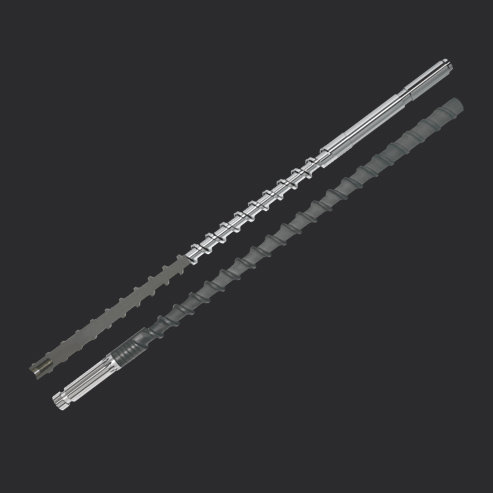

Alloy Grade B screw

The product thickness is thin, strong, easy to release, high yield, does not affect the imaging effect of high-speed dome camera, the picture accuracy rate is high, the image is clear, with high depth, distortion, high transmission rate and many other advantages

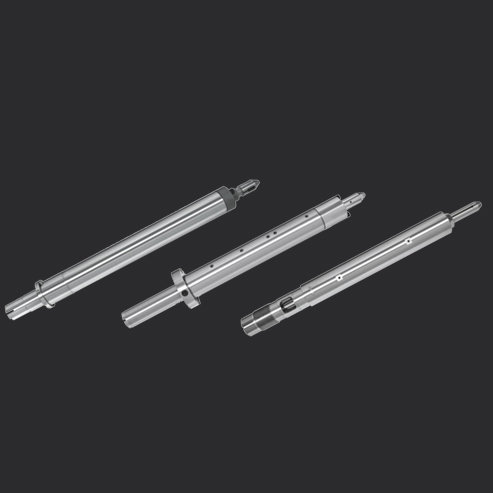

Universal top screw

Powder high speed steel and powder stainless steel, is the world's top industrial tool steel using powder cure method (atomized powder in the hot state for isostatic pressure treatment) HIP to produce dense billets, uniform organization, fine grain size...

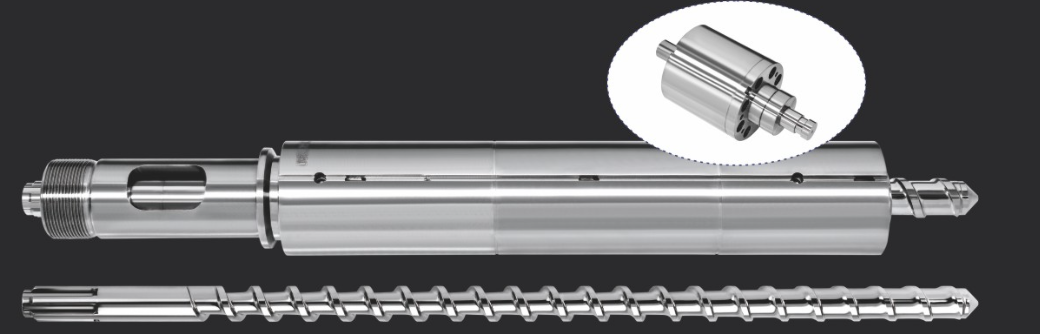

Clad alloy screw

The base material is made of high toughness and high hardness steel, and the surface of the screw is made of Ni-based, Ni+WC alloy powder fusion injection technology from the United States, which makes the working area of the screw alloy full cloak, with a thickness of 1~2mm and a bonding strength of about 210 bar...

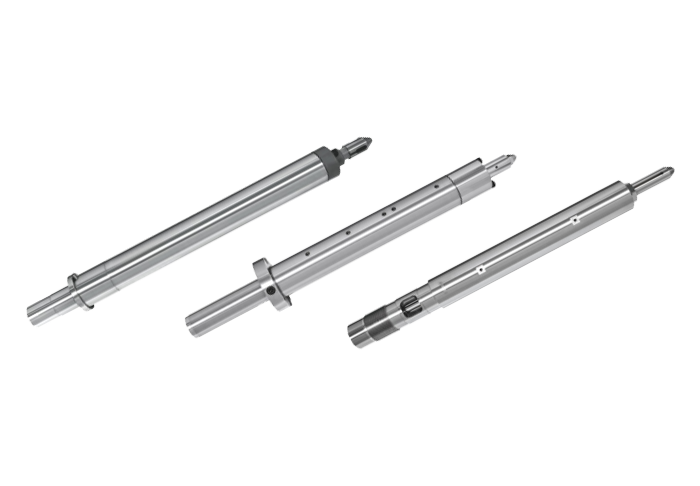

Nitriding screw/tube

High quality nitriding steel SACM645 or SKD61 is used for surface vacuum nitriding treatment after quenching, and the nitriding furnace is developed and improved to distribute the gas evenly in the furnace by means of leaf fan agitation...

Alloy material tube

Double alloy material tube is a layer of 2~3mm alloy powder casted in the inner hole of the material tube by high temperature centrifugal casting to enhance the wear resistance, corrosion resistance and high temperature resistance of the inner hole...

Recommended Products

Starmate has professional R & D design, production technology, product control and technical service team, advanced processing equipment at home and abroad, and international famous steel manufacturers, large heat treatment. We cooperate with international famous steel manufacturers and large heat treatment companies, select materials strictly and control heat treatment process strictly.

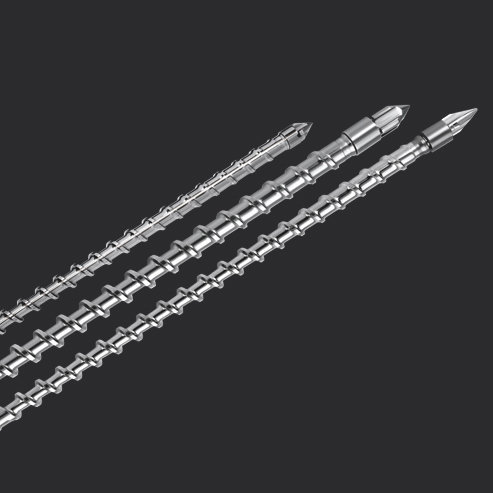

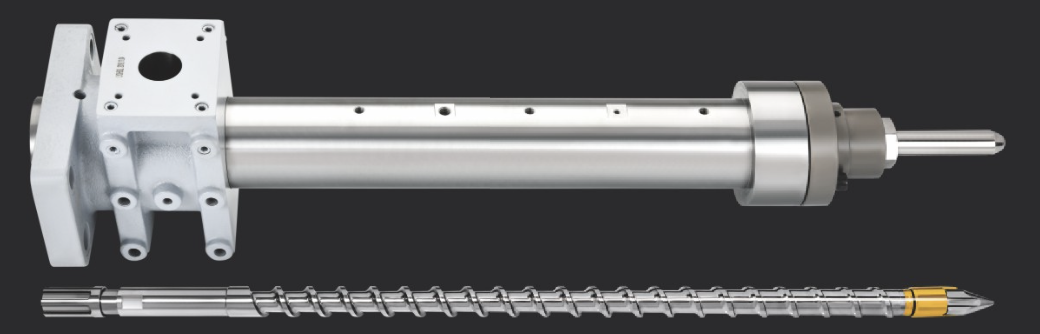

Injection Molding Screw/Tube

Sodick Screw/Tube

JSW Screw/Tube

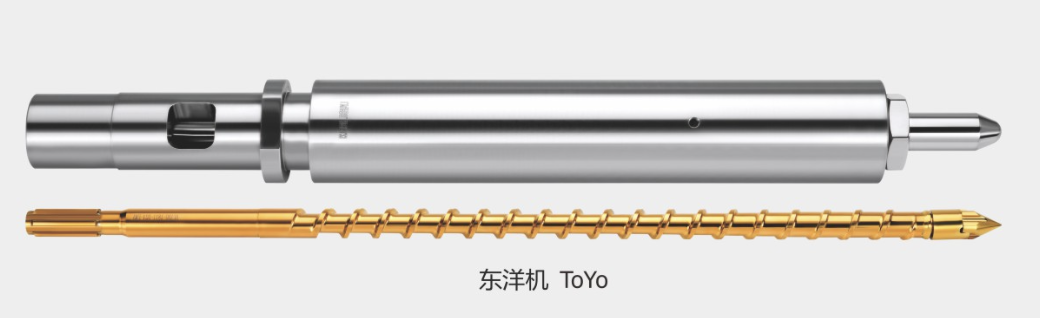

ToYo Screw/Tube

Nissei Screw/Tube

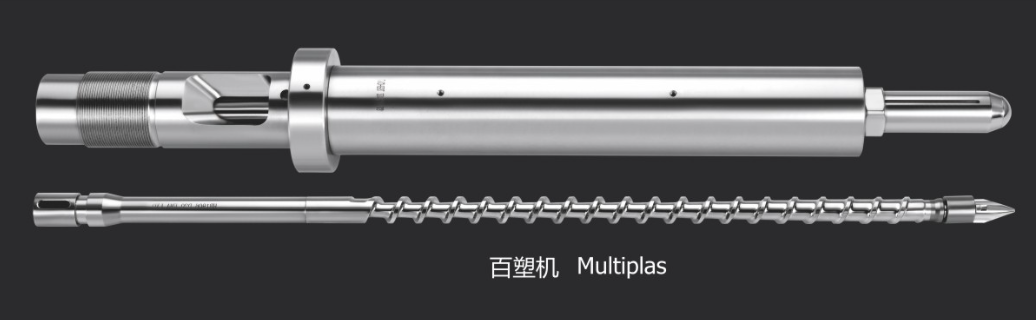

Multiplas Screw/Tube

Sumitomo Screw/Tube

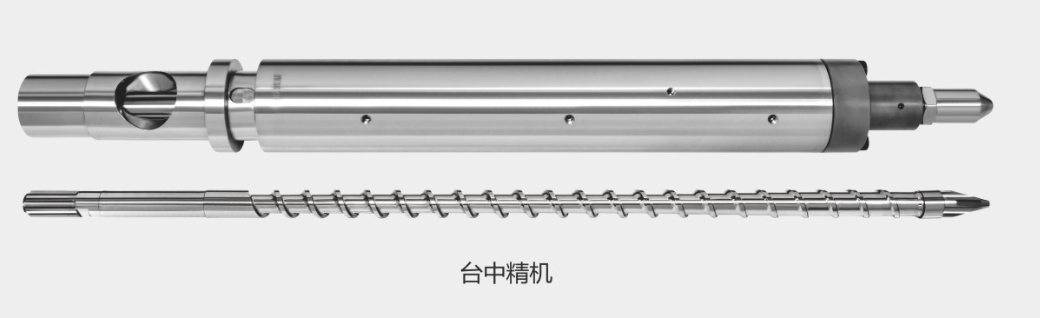

Taizhong Screw/Tube

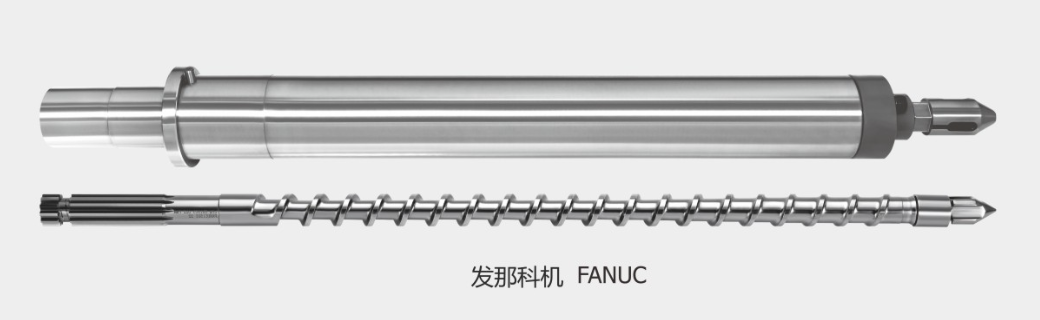

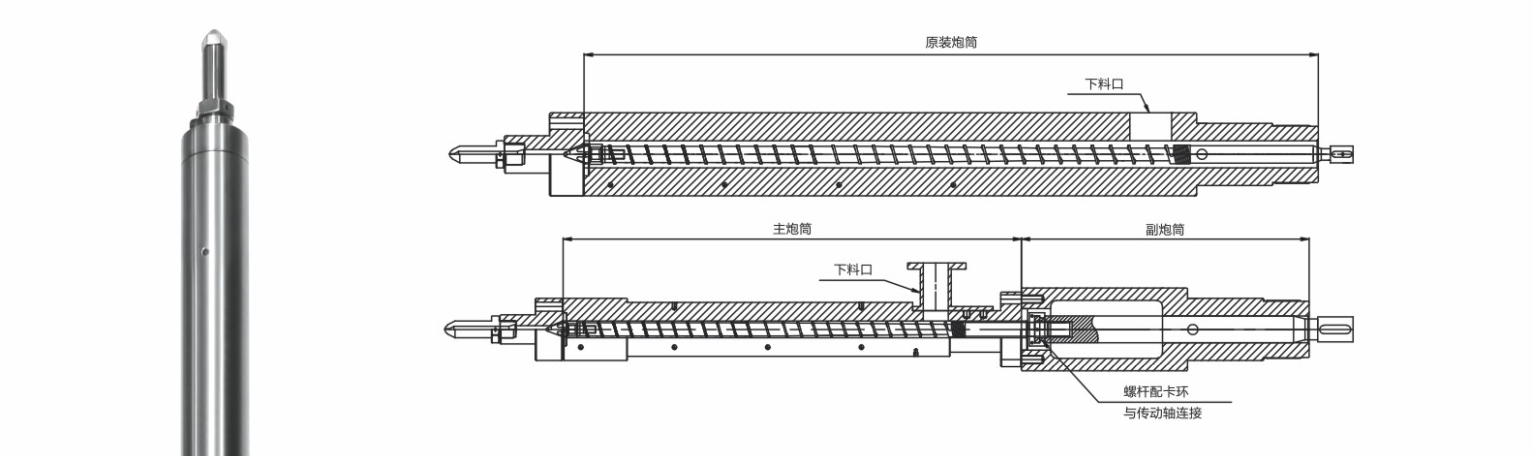

Fanuc Screw/Tube

NON_STANDARD TRANSFORMATION

According to the working conditions and raw material characteristics, from the selection of materials to the design,processing and maintenance,we will put "making plastic molding more stable and more efficient" in every detail

Professional Injection Molding Screw/Tube Supplier

"We are a professional supplier of injection molding screws, known for our precision and high-quality products. We are dedicated to providing exceptional solutions for injection molding and meeting the requirements of our customers.

Key Features:

High Precision: Our injection molding screws are manufactured with utmost precision using advanced techniques and state-of-the-art equipment. This ensures accurate dimensions and geometric properties, resulting in precise plastic flow and injection performance.

High Quality: We use only top-quality materials to ensure our screws exhibit excellent wear resistance, corrosion resistance, and heat resistance. Our rigorous quality control measures guarantee that each screw meets international standards and exceeds customer expectations.

Customization: We offer customized solutions to cater to specific application requirements. Whether it's size, pitch, or design specifications, we can tailor our injection molding screws to meet your unique needs.

Technical Expertise: Our experienced team of engineers provides professional technical support and guidance. We are here to assist you with material selection, design optimization, and troubleshooting during the injection molding process.

We prioritize customer satisfaction and continuously strive for excellence in all aspects of our business. If you are interested in our products or have any inquiries, please feel free to contact us. We look forward to partnering with you as your reliable supplier of high-precision and high-quality injection molding screws."

Business Partners