Plastic Caps and Plugs

Introduction

Here is the most complete guide on the internet about

You will learn:

- What are Plastic Caps and Plugs?

- Types of Plastic Caps and Plugs

- How Plastic Caps and Plugs are Made

- Uses for Plastic Caps and Plugs

- Plastics Used to Make Plastic Caps and Plugs

- And much more...

Chapter One – What are Plastic Caps and Plugs?

Plastic caps and plugs are two distinct ways for sealing the ends, tops, and openings of tubes and containers. Caps are placed over the opening, and plugs are placed in the opening. Due to the many varieties of containers, tubes, and cylinders, caps and plugs come in sizes, colors, and shapes to fit the needs of any application, including custom designs. There are an endless number of uses for caps and plugs. They can be found in industrial, commercial, and home products with special ones approved for use in food production.

The four varieties of polyethylene are used to make the majority of plastic plugs and caps, which are chosen for their ruggedness and strength. The type of material chosen is dependent on how a plug or cap will be used, since plastic materials for plastic containers can be less durable than plastics used for industrial masking and hydraulic pipes.

Other types of plastic plugs and caps include threaded and unthreaded ones that offer a tight seal and secure connection with a container. In some cases, plugs can act as both a plug and cap if they are threaded and flanged.

Chapter Two – How Caps and Plugs are Made

The process of producing caps and plugs is just as complex as that used to create any other form of plastic product, since they have to have the proper dimensions to fit the application for which they are engineered. Dip molding and injection molding are the processes most commonly used to produce plugs and caps since they are the types of processes capable of rapidly fabricating large quantities.

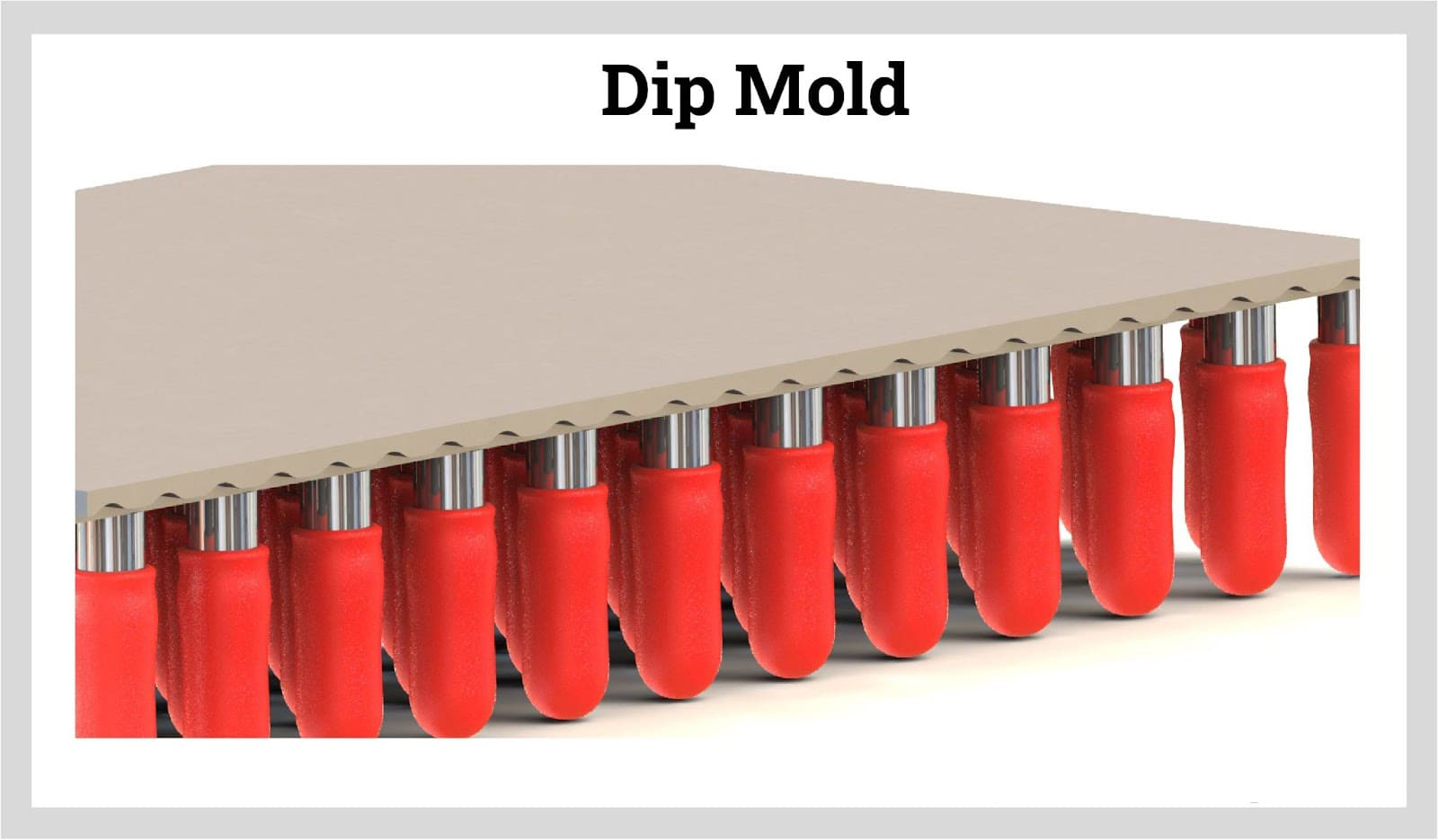

Dip Molding

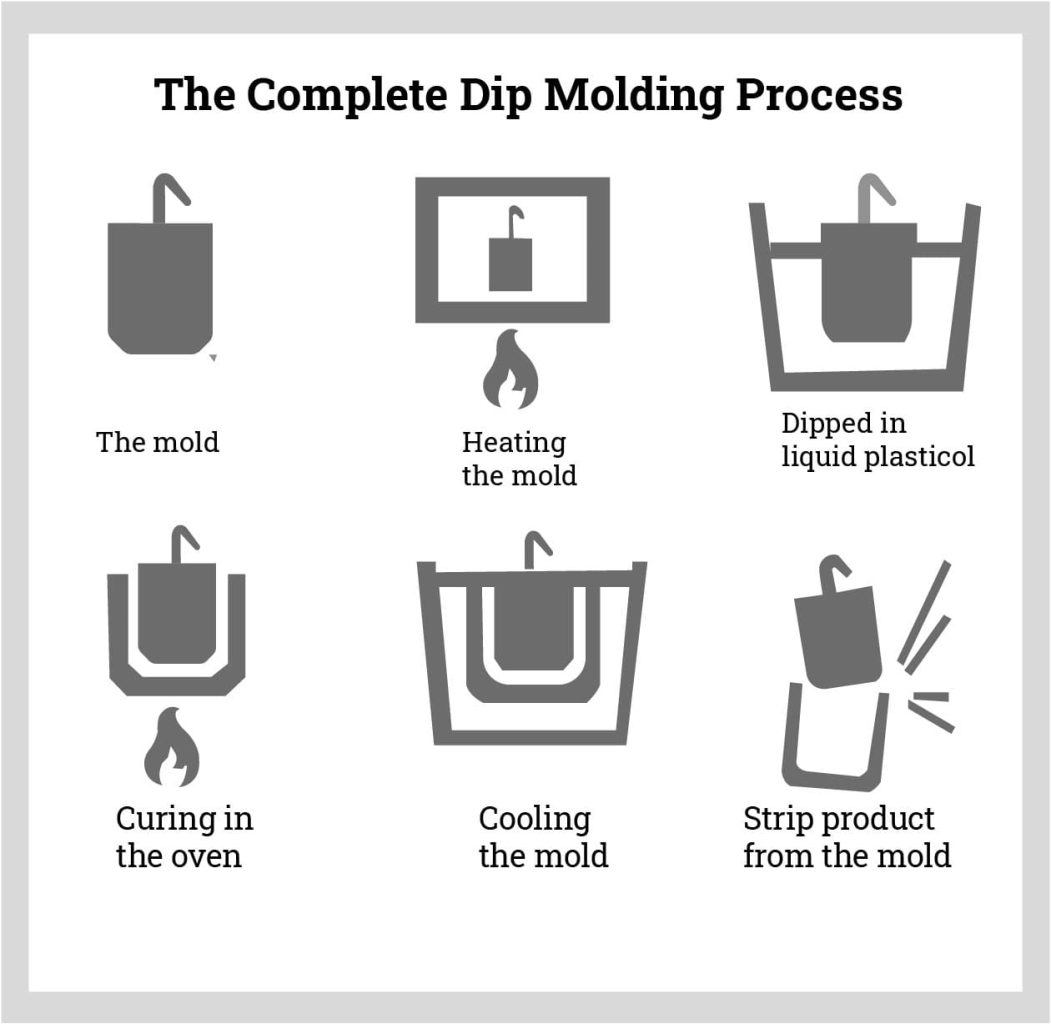

Dip molding is a process where a molding machine dips a mold into liquified plastic. As the mold sets in the liquid plastic, the plastic material adheres to the sides of the mold to create a reverse image of the mold. It is an ideal process for producing caps and plugs since it can produce several caps or plugs in a single step.

Selecting the Mold

The mold is the first step in the dip molding process since it creates the exact dimensions of the plug or cap. Dip molds are made of steel or aluminum and are created by a casting process.

Heating the Mold

In order for the mold to correctly form the plug or cap, it is placed in an oven and heated to a predetermined temperature to match the requirements of the design of the cap or plug. The temperature of the mold and the amount of time it is dipped determines the wall thickness of the product.

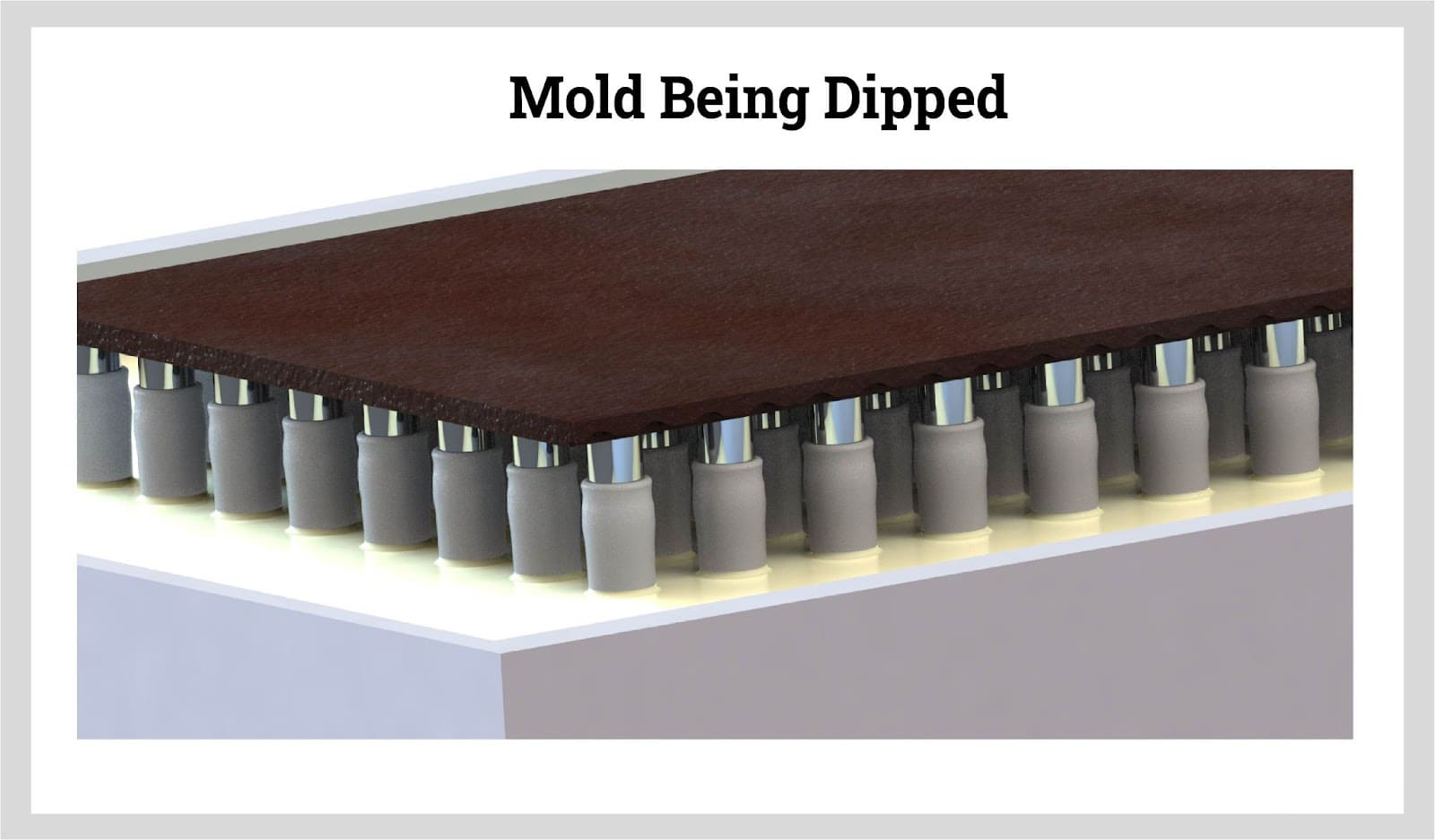

Dipping the Mold

The precision heated mold is then moved to the dip tank containing the plastisol, the general term for plastic material that can be converted into a solid plastic object. The speed at which a mold is dipped is carefully calculated and determined by the shape of the mold and its length. The speed may be varied to produce a more uniform and even surface for the product.

Curing the Mold

The wall thickness of a dipped mold increases as the time increases and can vary from several seconds up to a couple of minutes. Once the dip has reached the time limit, it is carefully removed at the appropriate speed. As is common with several molded products, the molded pieces are moved to a curing oven where the plastisol can harden and form.

Cooling the Product

The frame, mold, and products are cooled in water to allow them to be removed from the mold. Although they are being carefully cooled, the process is monitored and controlled such that it leaves residual heat, which makes it easier to remove molded items from the mold.

Product Removal

Removal of the products from the mold can be completed manually by hand or using pressurized air. Most manufacturers use a Federal Drug Administration (FDA) approved releasing agent to speed up the process.

Injection Molding

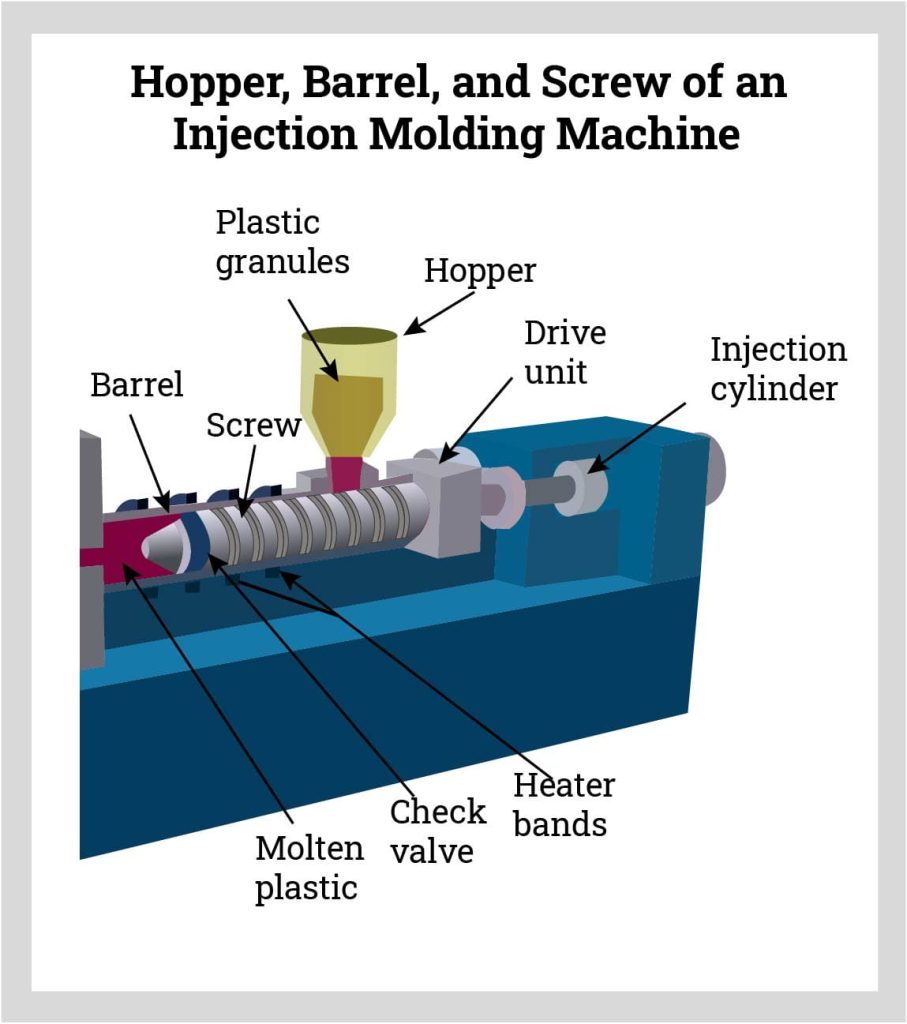

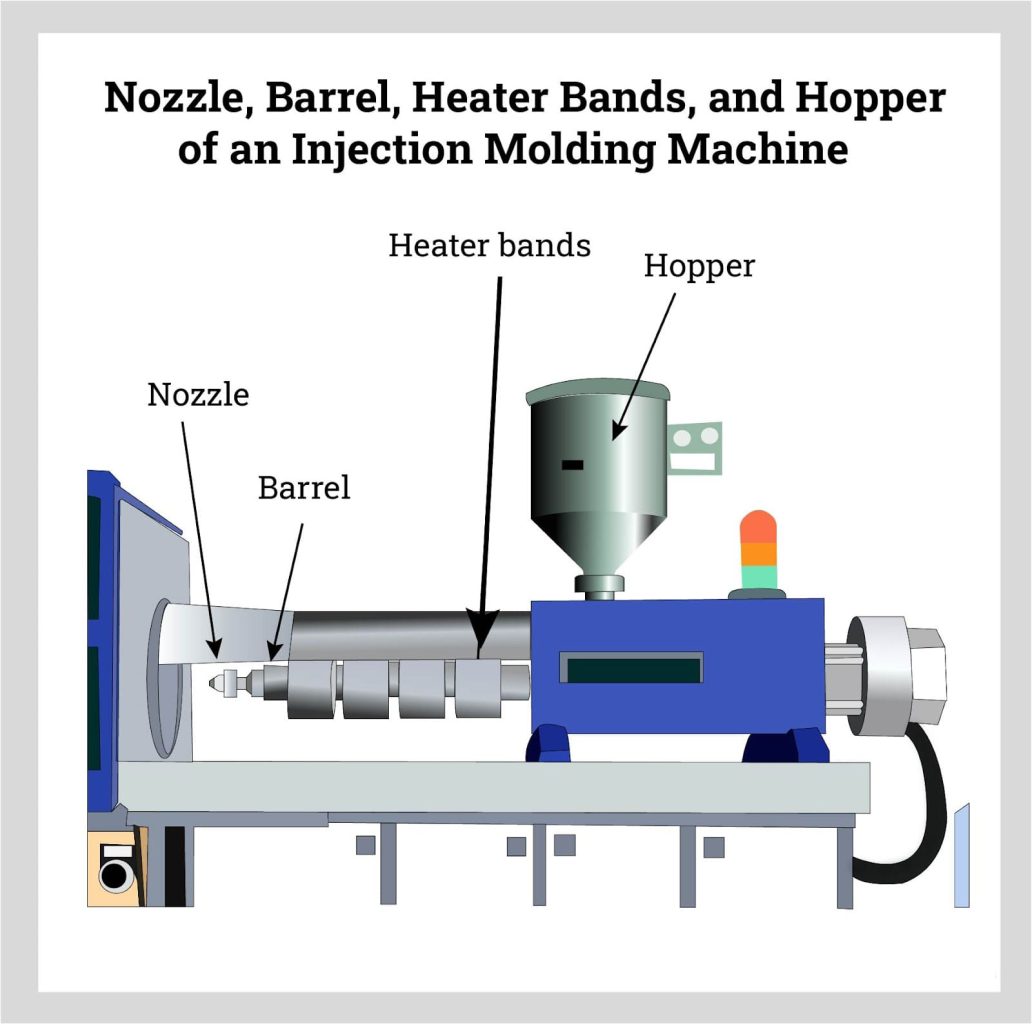

Unlike dip molding, injection molding begins with polyethylene terephthalate (PET) resin pellets that are poured or inserted into a hopper that is connected to a long tube or barrel that contains helical screws. Injection molding is cost efficient, capable of large production runs, and has high repeatability without any variations in dimensions, shape, thickness, or surface finishes. The main benefit of injection molding is its ability to meet tolerances, which is a necessity for threaded plugs or caps.

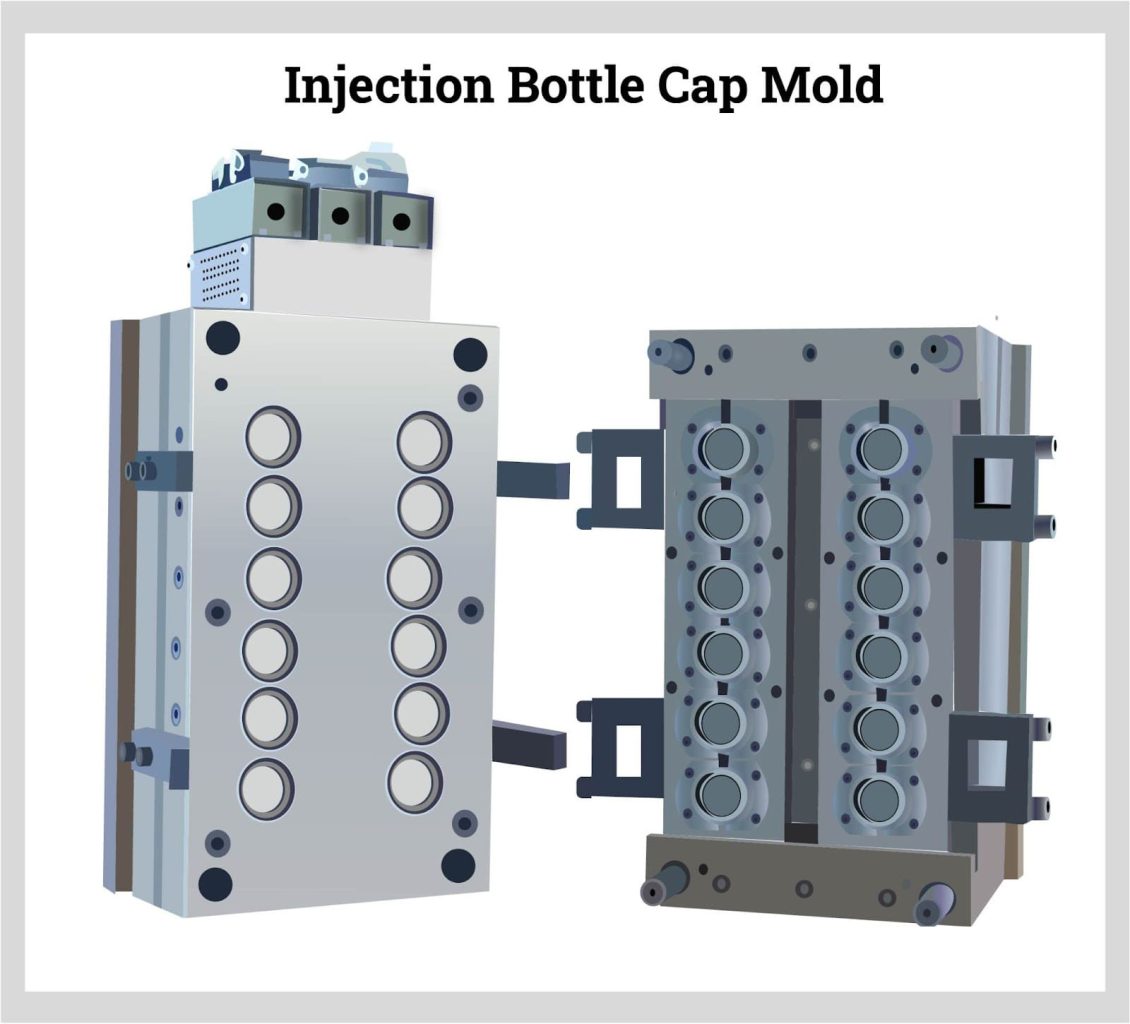

Mold Machining

The most expensive part of the injection mold process is the creation of the mold, which is carefully designed, crafted, and machined to perfectly match the shape and dimensions of the final product. The initial mold is created using computer aided design (CAD) software that can engineer any type of mold. Cap and plug molds have multiple die cavities that form a perfect impression of the product. Unlike dip molding, injection molds are capable of producing multiple completed products regardless of their complexity.

Filling the Hopper

The injection molding process begins with the hopper, where the raw PET pellets are poured into the barrel of the heating unit. Traditionally the hopper has a cone shape, but this has changed over the years to more technically controlled hoppers that can electronically monitor the flow of resin into the barrel.

Traveling Along the Barrel

In the barrel, the resin pellets are moved along by a helical screw toward a nozzle that is located at the end of the barrel. As the pellets are forced along, they are heated by heater bands placed around the barrel. Unlike in dip molding, the resin does not turn into a liquid but becomes soft and pliable so that it can be forced through the nozzle into the mold.

Injecting Into the Mold

During the movement along the barrel, the PET pellets are compressed and placed under great pressure as they soften before entering the nozzle. The force and pressure push the softened plastic into the mold, which is a tightly sealed steel, stainless steel, or aluminum cavity with the shape and dimensions of the caps or plugs. The increased pressure forces the soft plastic to completely fill the machined shapes such that they achieve the proper wall thickness and configuration.

Cooling the Mold

Once the mold has been completely filled, it is sent on to cooling, which is a critical stage of the manufacturing process. Proper cooling is necessary to ensure the molded plugs or caps solidify properly and do not deform or suffer damage. Properly planned cooling takes approximately 70% to 80% of the injection mold process. If the cooling process is well designed and engineered, it can radically improve and limit the time of production.

Demolding the Products

Much like the cooling process, demolding has to be handled carefully to avoid deforming and damaging the molded caps or plugs. The structure of the caps or plugs determines whether the demolding process is stripper or ejector, with ejector being the most common since it guarantees a stable and smooth release.

Leading Manufacturers and Suppliers

Chapter Three – Types of Plastic Caps

Plugs and caps perform the same function in different ways. Both are capable of being threaded or unthreaded and positioned over the opening of a container. The difference between them is in regard to how they are positioned with caps covering the outside walls of a container while a plug is placed inside the opening of a container.

Although plugs and caps are categorized as being similar, their unique way of closing and opening separates them into different designs and configurations.

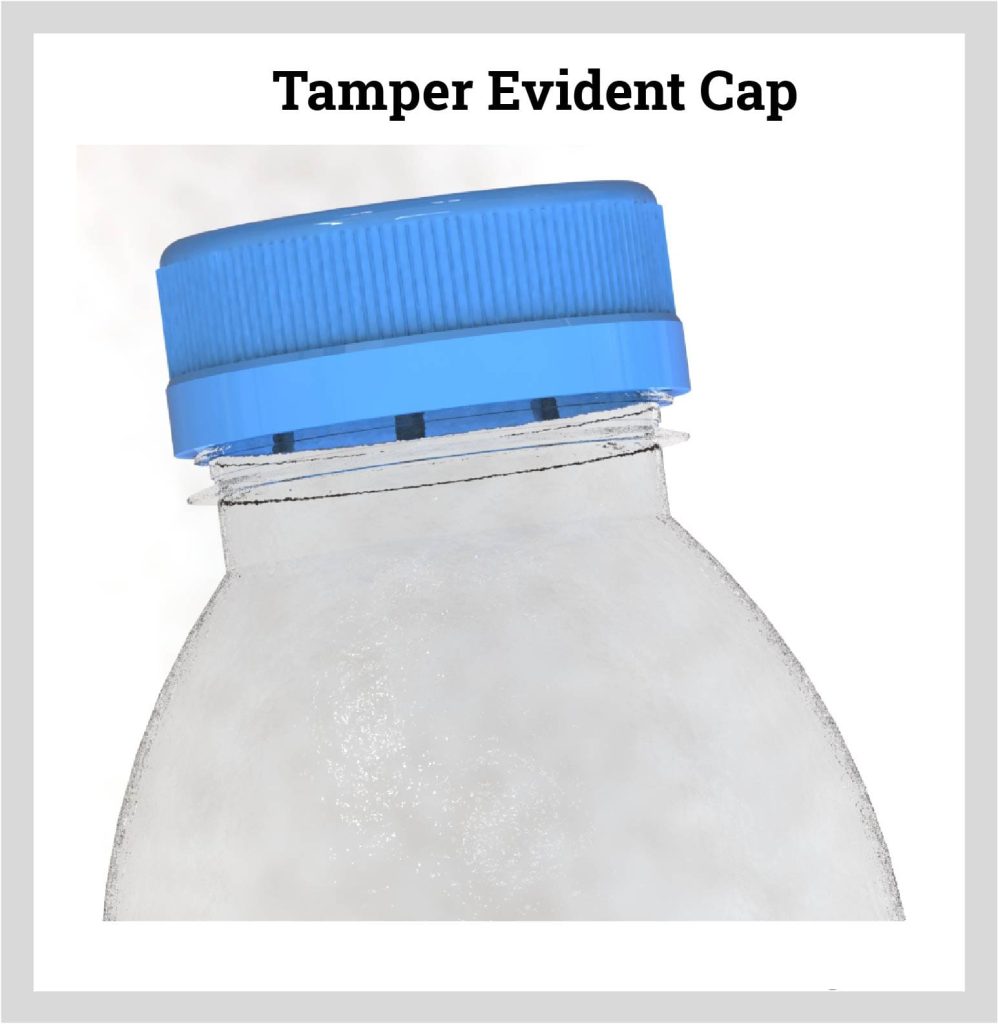

Tamper Evident Cap

Tamper evident caps have a small ring of plastic at the bottom of the cap that can be disconnected from the cap by twisting or turning the cap. They are produced using the same process as is used for other caps, but are sealed to a container using a shrink sleeve machine. The piece of plastic left on a bottle when a tamper evident cap is removed is referred to as a tamper evident band.

An important use of tamper evident caps is in the pharmaceutical industry, where they are used as an indicator that a bottle has had its cap removed.

Hex Caps

Hex caps are used on protrusions that have six sides. They are used as a method of protection and a finishing touch. Hex caps can be easily applied to form a tight and permanent connection. Of the various types of caps, hex caps are exceptionally durable and long-lasting with thick walls.

Utility Caps

Utility caps are designed to protect threaded connectors from damage. They are unthreaded pieces of plastic that slide easily over the threads of a protruding pipe and come in all sizes to tightly and snugly fit. Utility caps are made of low density polyethylene (LDPE) and can withstand temperatures of –94o F up to 175o F or –70o C up to 79o C.

Threaded Plastic Cap

Threaded plastic caps are a closing method for easily sealing ends or openings and can have ribbed or smooth sides. They come in a wide variety of diameters to appropriately fit the needs of an application. The convenience of threaded plastic caps makes it possible to seal and unseal a container multiple times, keeping the contents protected and fresh.

Recessed Caps

Recessed end caps protect the edge of pipes against damage. They are made of linear low-density polyethylene (LLDE), and they retain their resilience at temperatures of –94 oF up to 194 oF or –70 oC up to 90 oC.

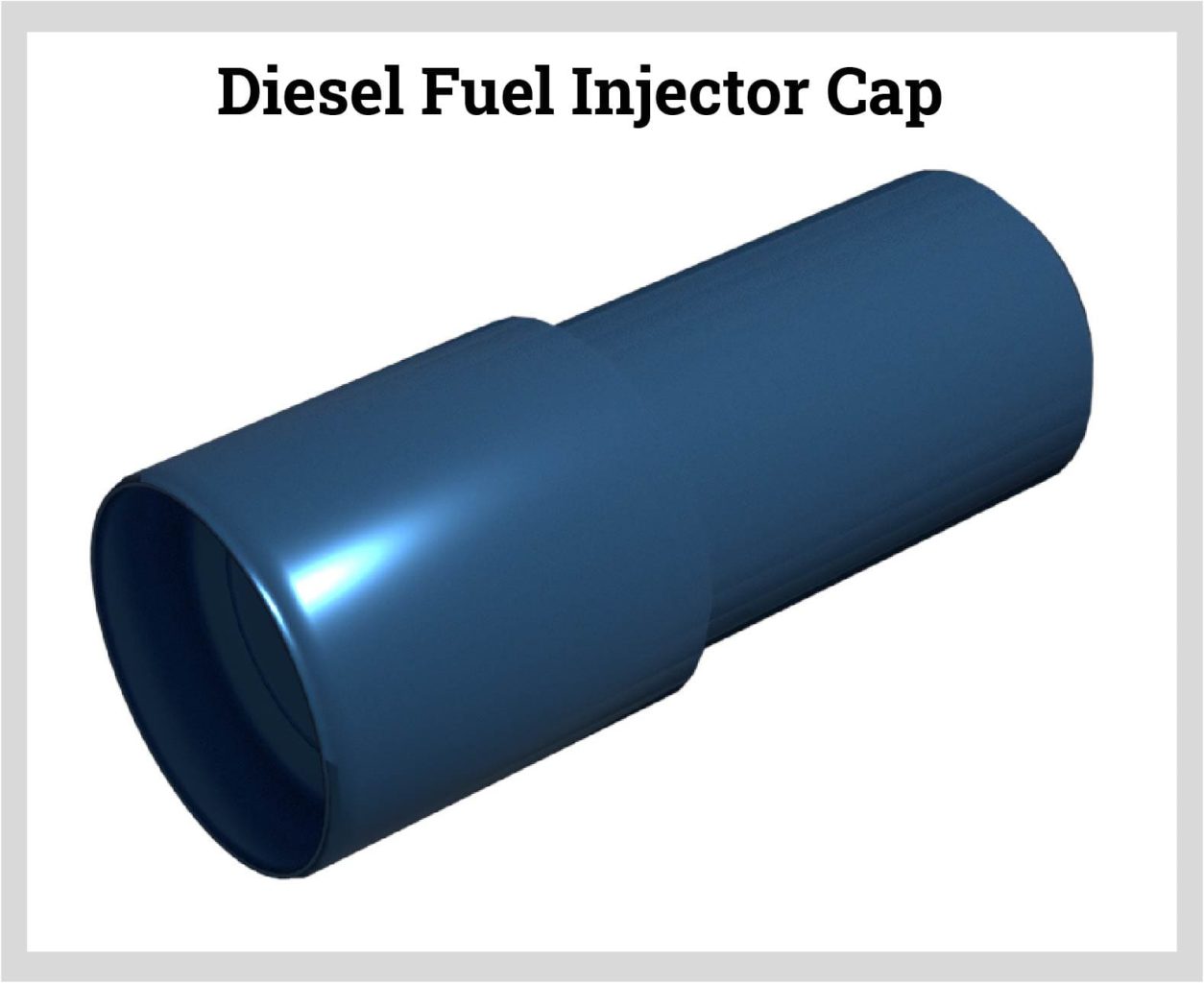

Diesel Fuel Injector Cap

Diesel fuel injector caps are designed to protect injectors from damage during transport and to keep out moisture and contaminants. They are an economical and efficient protection method made of LDPE.

Pull Tab Cap

Pull tab caps have a long tab at the center of the top of the cap that allows for quick and easy finger removal of the cap. They eliminate the need for tools when removing a cap from the threads that it protects. Pull tab caps are designed for protection of threads during painting, plating, and powder coating applications. The unique structure and endurance of pull tab caps make it possible for them to withstand temperatures of 500 oF for intermittent use and 300 oF for continuous use.

Tear Tab Cap

Tear tab caps are somewhat similar to pull tab caps because they also have an extended piece of plastic that allows them to be removed quickly. Unlike pull tab caps, tear tab caps have their tab located on the side of the cap. When the tab is pulled, it tears away part of the cap for easy removal.

Summary

The eight caps described above are a small sample of the hundreds of different caps that are produced by manufacturers. Essentially, there is a cap to fit any type of application regardless of the conditions or environment. Additionally, producers work closely with customers to create specially designed customized caps for unusual and unique applications.

Chapter Four – Types of Plastic Plugs

Plastic plugs are a protective tool for butt weld ends on valves, pumps, and heat exchangers. They are designed with characteristics and properties to meet the needs of any application, regardless of how stressful or hazardous the conditions may be. Aside from their industrial use, plastic plugs are used for capping the ends of patio furniture, fence posts, and shipping tubes.

The tight and secure seal of plastic plugs ensures that the contents of containers or pipe ends are well protected and help in avoiding spills and losses. Unlike caps, plastic plugs fit snugly inside the walls of the opening of a container or pipe and are normally forced into the opening to guarantee a tight fit.

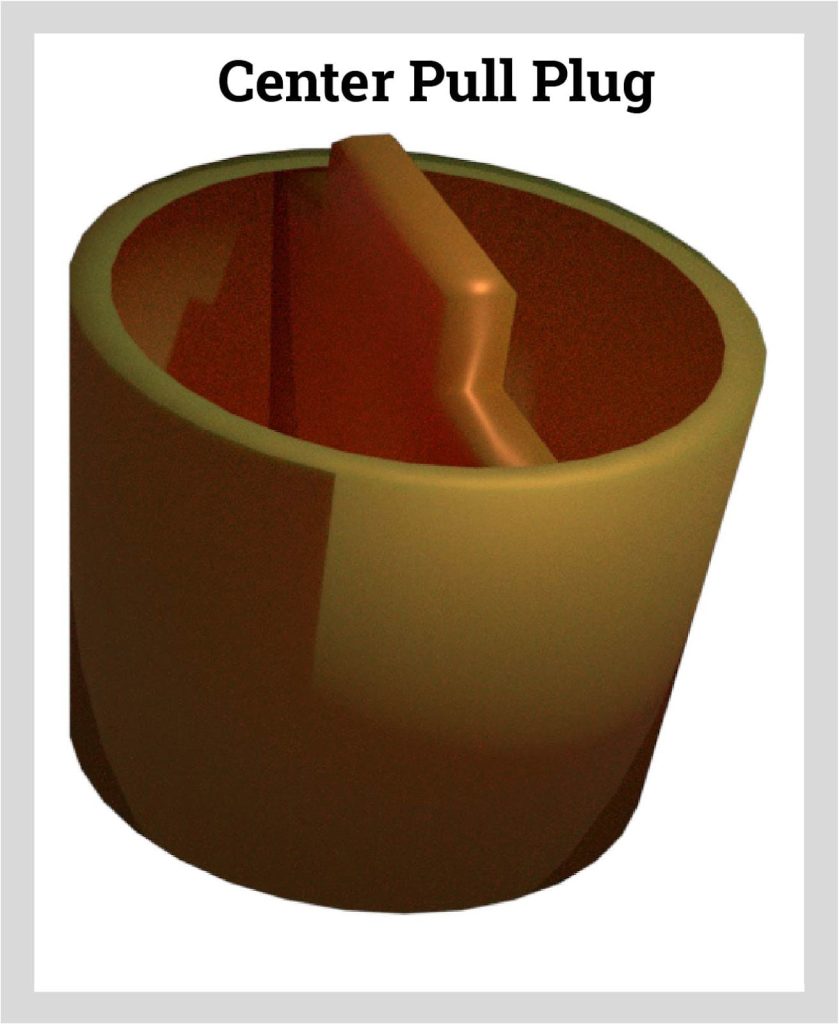

Center Pull Plugs

Center pull plugs function much like pull tab caps, but have the pull tab located inside the center of the plug. They are ideal for conditions where two close-by openings have to be plugged, but there isn’t any room for a flange. They have a tapered design for easy installation and come in sizes to fit any opening.

Suspension Plugs

Suspension plugs provide durability and strength for supporting heavy rolls. They provide the stability and ruggedness required for holding rolled materials that can be suspended from rolling racks or wall mounted brackets.

Core Plugs

Core plugs are designed to support heavy rolls and fit tightly in both ends of a roll. They are commonly found in the ends of craft and butcher paper rolls. The tapered design of core plugs makes them easy to install and remove when rolls have to be changed. Since they fit flush to the end of the roll, they make it easy to stack rolls or stand them on end.

Quick Release Plugs

Quick release plugs make it easy to connect and disconnect airlines from a compressor or air tool. They are designed to seal without the use of sealant or tape. Quick release plugs are attached to a hose and protect against dirt, moisture, and corrosion. They are capable of functioning in environments as low as –40 oF (–40 °C) or as high as 275 oF (135°C) and comply with ISO 7241-1 for quick couplings.

Threaded Plugs

On a female threaded fitting, the threads are on the inside of the fitting, which makes it possible for a male fitting to be screwed into a female fitting. This type of design creates a tight connection between pipes without the need for gluing PVC pipes together. To seal off such connections, a threaded plastic plug is used to securely and tightly close off the end of a pipe to keep out dirt, moisture, and contaminants. Additionally, threaded plugs can be used to seal off a line during pressure testing.

Masking Flangeless Plugs

Masking flangeless plugs are designed to plug threaded holes. They have a tapered hollow shank that makes it possible to insert them in any size hole. They are capable of masking a hole without masking the surrounding hole area. Masking flangeless plugs are made of polyvinyl chloride (PVC) plastic, which makes them durable, resistant to abrasions, and resistant to chemicals.

Plastic Plug Shapes

The most common form of plug, regardless of the application, is round and tapered. Although they are ideal for most situations, there are conditions that require square and rectangular plugs, which are made of the same materials as round plugs. As with round plugs, square and rectangular plugs are used in a wide variety of applications due to their durability and strength.

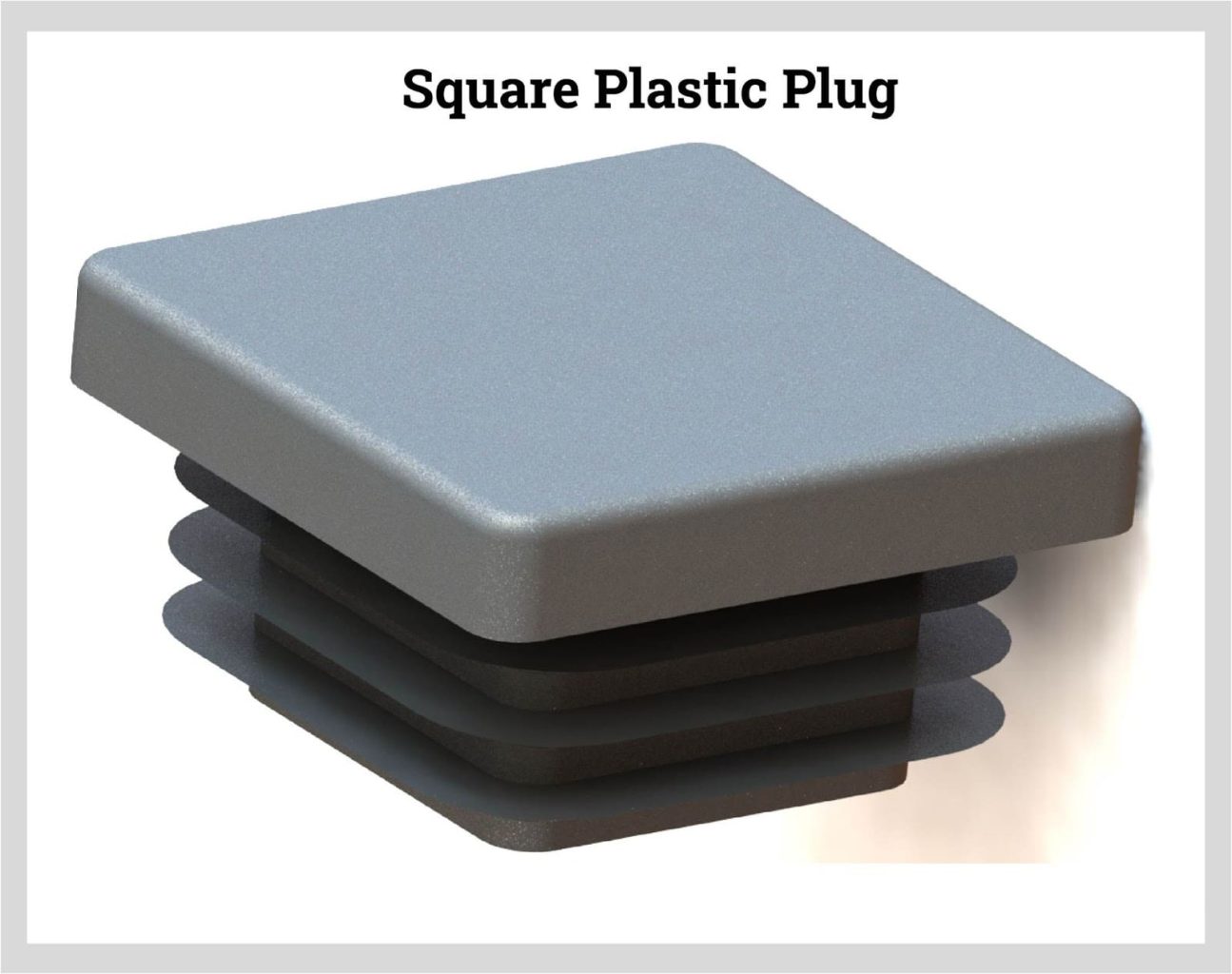

Square Plastic Plugs

The most common use for square plastic plugs is sealing and securing square ended tubes. They can be found at the ends of chair legs to create a finished appearance on display cases, various metal products, and plastic shipping tubes. Square plastic plugs are made of pliable and soft LDPE in tube sizes from a half inch (1.3 cm) up to a little less than 5 inches (12.7 cm).

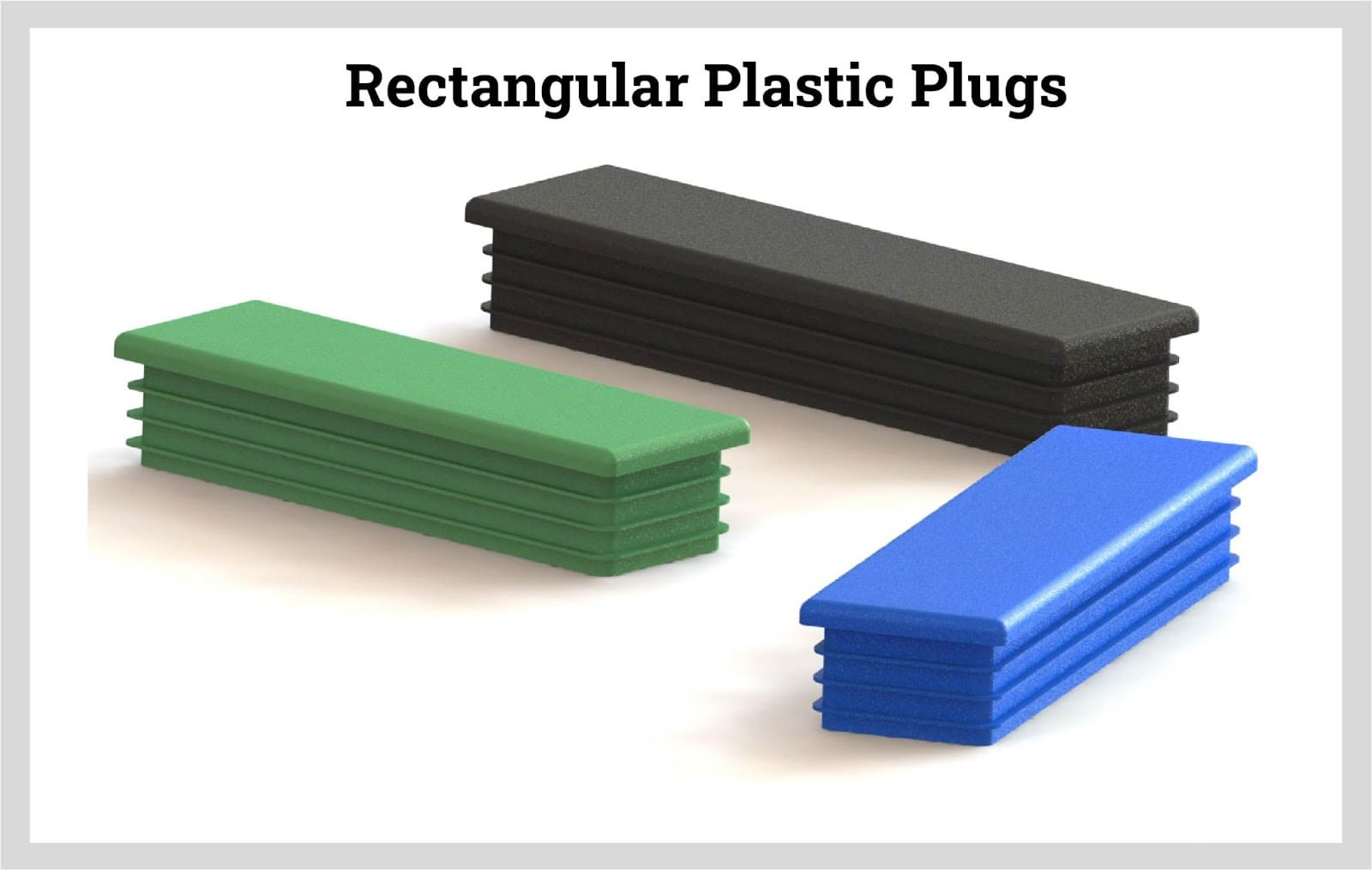

Rectangular Plastic Plugs

Rectangular plastic plugs function much like square plastic plugs as aesthetic accents for furniture or sealing for metal tubing. They are designed to fit stands for computers, office machines, display cases, and equipment with rectangular attachments. Since they are weight bearing, they are made of highly durable and strong polyethylene. Some designs have ribbing to enhance their grip on the internal walls of tubing.

One of the key aspects to rectangular and square plugs is their wall thickness, which is a determining factor in the amount of abuse they can withstand. The wall thickness for plastic plugs is categorized in gauges, as with metals, with low numbers indicating thick walls and higher numbers indicating thin walls. Typical gauges for plastic plugs begin at 3 gauge, or 0.259 inch (6.58 mm), and extend to 0.035 inch (0.89 mm) or 20 gauge. As is common with metals, wall thickness determines how a plug can be used and its life of usefulness.

Summary

The few varieties of plugs described above are an extremely small sampling of the wide array of plugs that manufacturers have to offer. From plugs for hydraulic lines to ones for piping, there is a plastic plug to fit any application in addition to custom made plugs for unique and special applications. Plastic plugs are an essential part of modern production and have been adapted and perfected to fit any environment or conditions.

Chapter Five – Plastics Used to Manufacture Plugs and Caps

Plug and cap manufacturers have several types of plastics to choose from when deciding to produce their products, since each type of plastic has properties and characteristics to fit any application. The various polyethylene plastics are used the most since they come in different types and are known to be able to withstand the demands of constant use.

The type of plastic is determined during the design phase of engineering. Using the parameters provided by customers or the demands of an environment, a plastic is chosen to perfectly match a plug or cap’s working conditions. This aspect of production ensures that a product will be able to endure and last.

Low Density Polyethylene (LDPE)

LDPE is a rigid plastic that has high impact strength. It is capable of withstanding temperatures as low as 32 oF (0 °C). LDPE is usually the first choice for the manufacture of plugs and caps due to its low cost. It is used as protection during product and equipment transport.

High Density Polyethylene (HDPE)

HDPE has excellent chemical resistance and low permeability to gasses and moisture. It is one of the most versatile of the plastics and is known for its strength and strength-to-density ratio. HDPE is impact resistant and has a high melting point. The texture of HDPE forms a strong grip, which makes it ideal for the production of caps and plugs.

Polyvinyl Chloride (PVC)

PVC is a high density plastic that is resistant to deformation due to impact. It is exceptionally durable and resistant to weathering, making it ideal for outdoor applications. It has exceptional strength and endurance and is a long-lasting, low-maintenance plastic capable of performing for years without needing to be replaced. With low thermal conductivity, PVC can be used in high temperature applications without melting or losing strength. It has excellent dielectric strength, which makes it ideal for applications where nonelectrical conductivity is necessary.

Nylon Material

Nylon is known for its strength and toughness. Its crystalline structure makes it stiff and abrasion resistant. It is used extensively in the production of plugs such as threaded sealing plugs and solid locking plugs. Nylon is ideal for use in the production of blanking plugs due to its excellent aesthetic appeal.

Polypropylene (PP)

Polypropylene is normally used to manufacture caps due to its impact strength, cost effectiveness, and pliability. It is a tough material that does not suffer from stress cracking and has such excellent fatigue resistance that it keeps its shape after being subjected to torsion. Since it is a nonelectrical conductor, PP caps are widely used in electrical applications.

Thermoplastic Rubber (TPR)

In some ways, TPR is the ideal material for the production of caps and plugs since it has all the properties of rubber with the forming properties of plastic. Much like rubber, TPR is flexible and will hold its shape regardless of any condition. It is often used for masking protection.

Chapter Six – Uses for Caps and Plugs

Simple plastic caps and plugs seem to be inconsequential, small pieces of plastic that cover holes and serve as stoppers. This interpretation of their usefulness may be overlooking how essential they are for industrial processes where they protect equipment from potential damage and contaminants. The action of closing off a pipe, plugging an opening, or capping a line can be a crucial and relevant part of a complex application. It is in these conditions that plastic caps and plugs become an important part of a larger and more complex operation.

Hydraulic Systems

Hydraulic systems can be seriously damaged by contaminants entering the system. Although contamination can occur while a system is in operation, much of it is present when a system is installed, which is due to the system being shipped without protection for the hydraulic lines. Caps and plugs can serve as protective tools when a hydraulic system is in operation. They provide a greater service when a system is being shipped and set up.

Children’s Toys

Plastic caps and plugs are used as safe and protective tools for children’s toys. They are placed over sharp uneven edges, rough corners, and the heads of exposed screws and bolts to avoid cuts. Caps and plugs serve as finishing accents on toys where there may be unnecessary holes or openings. Round, square, and rectangular plastic caps are commonly found on children’s toys as a finishing accent or safety precaution.

Industrial Painting

When machines, vehicles, and equipment are being painted, parts that need protection are covered with paper or other protective materials. When the area around an opening is to be painted, it is necessary to ensure the opening is protected from paint. In some instances, wads of paper are stuck into an opening, which is not a uniform solution and can slow down the efficiency of the painting process.

To assist in the efficiency of a painting operation, masking plugs are used that are tapered to fit into any opening and have a large tab for quick and easy installation. They can be inserted and removed effortlessly, keeping painting processes constantly moving.

Product Finishing

Furniture, playground equipment, various tools, and store displays have uncovered ending pipes, tubes, and cylinders that can make them look as though they are unfinished or incomplete. Plastic caps and plugs are used to cover such openings and provide a sleek and uniform finished look that enhances a product.

Product Shipping

Shipping tubes are a very common tool for shipping blueprints, maps, artwork, and other documents. They are sturdy, durable, and impenetrable, which makes them the perfect choice for protecting sensitive information and materials. Although the tightly wrapped cardboard exterior serves as excellent protection, it is difficult to shape it to cover the ends of the long tubes.

Exterior plastic caps, threaded or unthreaded, are used to securely and completely cover the ends of shipping tubes. Since they can be manufactured to the exact required dimensions, plastic caps can be permanently attached or temporary depending on their design and use.

The most common form of sealing for shipping tubes is plastic plugs, which come in a wide variety of sizes, designs, and shapes. In many cases, plastic plugs are configured to permanently seal one end of a shipping tube while the other end is covered with a cap or removable plug.

Product Protection

During shipping, protrusions on products can be exposed to damage as part of shifting and movement during transport, which can lead to bent ends, damaged openings, and other types of harm. Shock absorbing caps are an ideal way for providing the necessary protection to ensure a product arrives in the best possible condition. Their flexibility makes it possible to create the perfect wall thickness, diameter, and shape to fit the needs of a product.

Bumpers

Traditionally, rubber has been used as bumper material because of its resilience and strength. In certain conditions, the expense and durability of rubber is not necessary. In those conditions, plastic caps and plugs are the ideal choice since they can have the same resilience of rubber but at a lower cost. Additionally, plastic caps and plugs can be shaped, configured, and designed to fit any type of protective need, regardless of the environment.

Conclusion

- Plastic caps and plugs are two distinct methods designed to seal the ends, tops, and openings of tubes and containers. Caps are placed over the opening, and plugs are placed in the opening.

- The choice of plastic material used to manufacture caps and plugs is dependent on how a plug or cap will be used, since caps or plugs for plastic containers can be less durable than ones for industrial masking and hydraulic pipes.

- Plastic plugs and caps perform the same function in different ways. Both are capable of being threaded or unthreaded and positioned over the opening of a container. The difference between them is in regard to how they are positioned, with caps covering the outside walls of a container while a plug is placed inside an opening.

- Plastic plugs are a protective tool for butt weld ends on valves, pumps, and heat exchangers. They are designed with characteristics and properties to meet the needs of any application, regardless of how stressful or hazardous the conditions may be.

- Simple plastic caps and plugs seem to be inconsequential small pieces of plastic that cover holes and serve as stoppers. This interpretation of their usefulness may be overlooking how essential they are for industrial processes where they protect equipment from potential damage and contaminants.