Polyurethane Molding

Introduction

This article takes an in depth look at Polyurethane Molding.

Read further to learn more about topics such as:

- What is Polyurethane Molding?

- History of Polyurethane Molding

- Properties of Polyurethane

- Polyurethane Molding Processes

- And much more…

Chapter 1: What is Polyurethane Molding

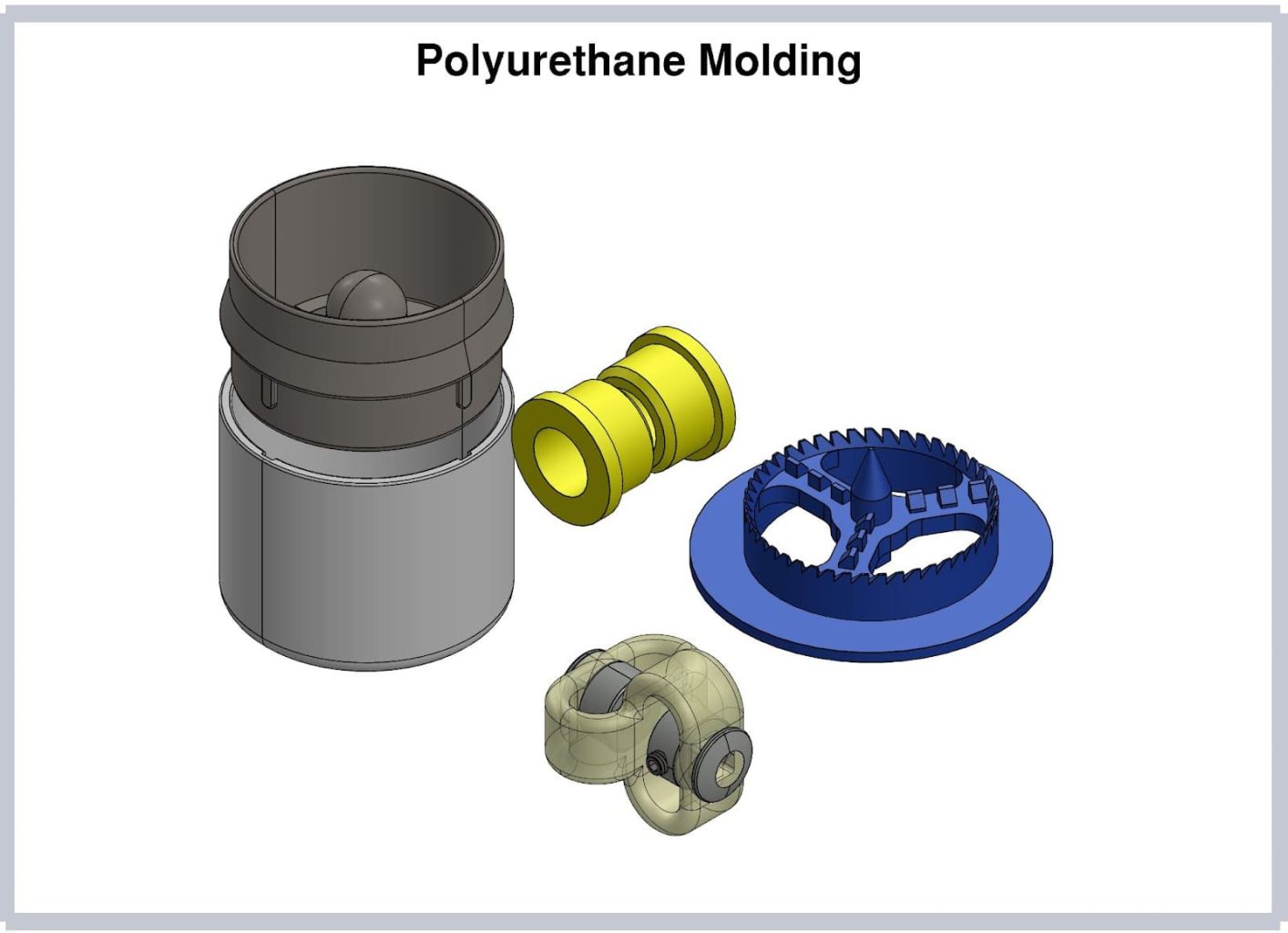

Polyurethane molding is the process of fabricating or manufacturing plastic parts by introducing a urethane polymer system into a tool or mold and allowing it to cure. Like any other type of plastic, the excellent processability of polyurethane makes it very efficient in the fabrication of common consumer goods and industrial parts. In addition, polyurethane molding easily achieves tight tolerances and complex geometries.

Polyurethanes are extremely versatile materials that can have various formulations to yield different plastic properties. Their mechanical properties can vary from very soft and pliable to hard and rigid. Specific compounds can also make them into high-performance, engineering-grade products.

Polyurethane moldings are extensively used in:

- Furniture (cushions, underlays, covers)

- Construction (building insulation)

- Automotive and transportation (bumpers, bushings, fenders)

- Industrial and manufacturing equipment (rollers, cams, wheels)

Chapter 2: History of Polyurethanes

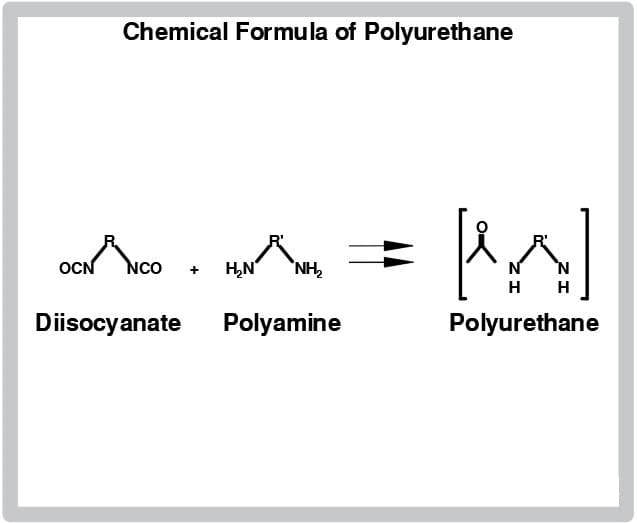

The discovery of polyurethanes is attributed to Otto Bayer in 1937 when he worked with coworkers at the laboratories of I.G. Farbenindustrie A.G. in Germany. The first polyurethane was formed from the reaction between a diamine-forming polyurea and an aliphatic diisocyanate. The polyurea was later replaced by glycol due to the enhanced properties of the polyurethane created.

The early forms of polyurethane were used during World War II. The original intent was for polyurethane to act as a synthetic substitute for natural rubber, which at that time had an exceedingly high demand and was difficult to obtain. The versatility of polyurethane gave it potential applications in fiber, foam, and coating production. This stimulated the commercial use of polyurethanes in the manufacture of textiles, cushions, shock-absorbing pads, and metal finishing.

The availability of polyisocyanates in 1952 led to the widespread use of polyester-isocyanate urethane systems. A few years later, polyether polyols in the form of poly tetramethylene ether glycol (PTMEG) were introduced in 1956 by DuPont. The next year, BASF and Dow Chemicals developed polyalkylene glycols. These two developments paved the way for the commercial introduction of polyether-based urethane systems. They offered superior characteristics to those exhibited by polyester systems. Such characteristics are excellent processing, low-temperature stability, and resistance to water and humidity. Since then, they‘ve become the major polymer system in the polyurethane manufacturing industry.

Leading Manufacturers and Suppliers

Chapter 3: Properties of Polyurethane

Polyurethane is an excellent plastic molding material because of its many desirable characteristics. Some of these properties include hardness, resilience, and chemical resistance. Polyurethane materials can be engineered to have different mechanical and chemical properties by formulating the polymer system with different components blended in specific quantities.

Hardness

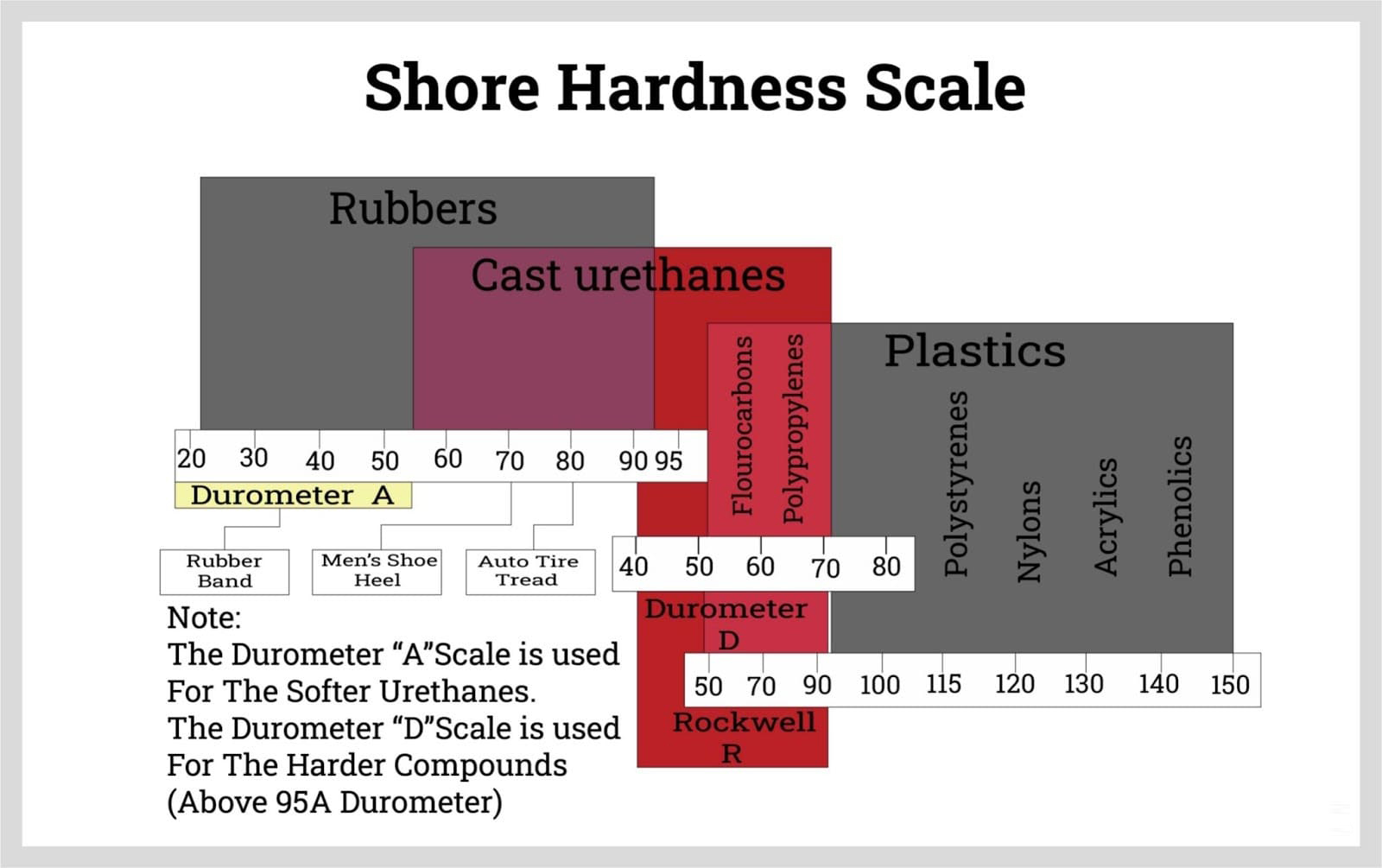

Hardness is the relative resistance of a material to localized surface deformation. It is usually determined by measuring the depth of indentation on the material by a standard indenter, ball, or presser foot.

Materials are graded according to their hardness relative to one another. For elastomers, hardness is characterized by the Shore Hardness Number and measured by a durometer. The Shore hardness scale is categorized into 12 scales; each scale has its indenter configuration, profile, and force applied. The Shore scales used for polyurethanes are Shore A and D. The Shore A scale measures the hardness of soft, semi-rigid polyurethanes, while Shore D measures hard and rigid polyurethanes. However, remember that high hardness does not correspond directly to high rigidity or strength.

Abrasion Resistance

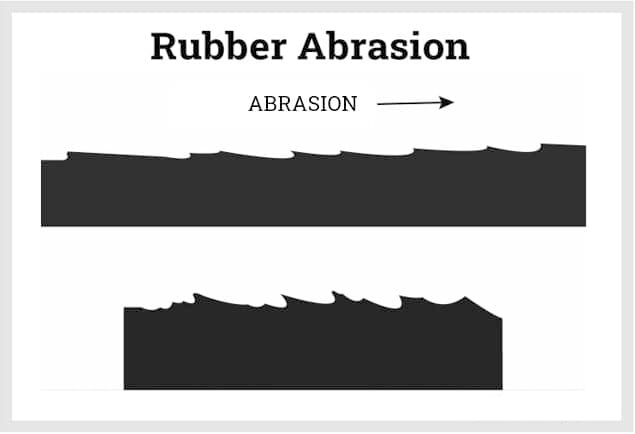

Abrasion can be classified into two types: sliding and impingement abrasion. Sliding abrasion occurs when a hard material like metal or ceramic slides or rubs into a softer material with or without contaminants between the surfaces. Impingement abrasion, in contrast, happens when particles impact the surface, causing erosion.

Polyurethanes with a low coefficient of friction and high tear strength offer good sliding abrasion resistance, while polyurethanes with good resilience are used for impingement abrasion. Resilient polyurethanes can yield elastically, allowing forces from the impacting particles to be distributed on the surface.

Abrasion resistance is achieved by the right composition of the polyurethane resin. Among the polyol compounds for making polyurethane, polyesters exhibit better tear and abrasion resistance.

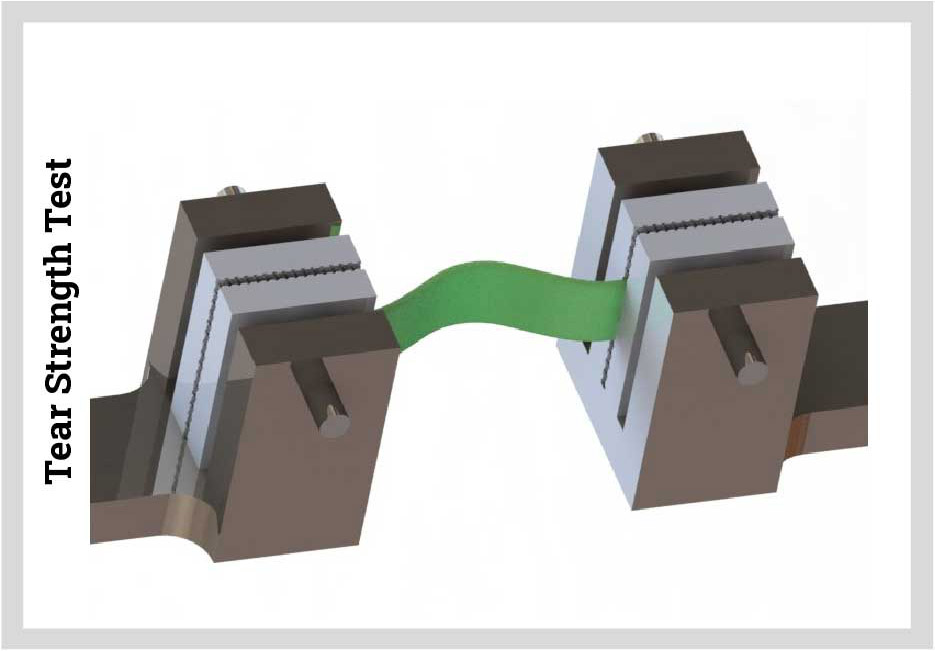

Tear Strength

This is the ability of polyurethanes to withstand the application of tensile forces that tend to rip the material apart and propagate the tear throughout the body of the material. Tear propagation can vary depending on how the force is applied and the microscopic structure of the material. Tear strength can sometimes be correlated to abrasion resistance. Polyurethanes are known to have both good tear strength and abrasion resistance.

Impact Strength

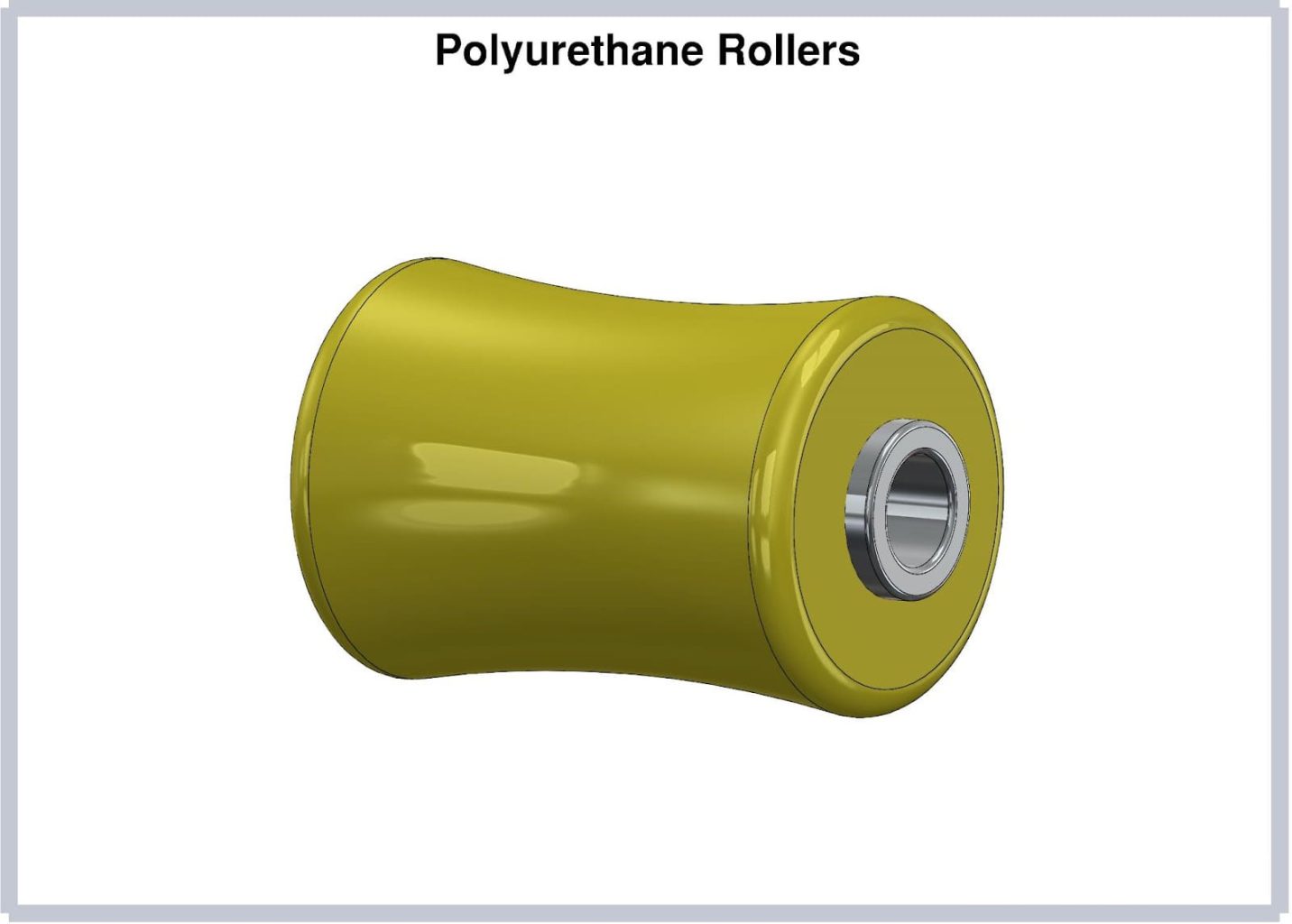

As with abrasion resistance, polyurethanes possess good impact strength because of their excellent resilience. The polyurethane lining used in rollers can elastically deform to absorb the impact and return to its shape. All this while dissipating the energy throughout the structure of the roller.

Fatigue Resistance

Polyurethane has high fatigue resistance because of its flexural strength. It can elastically deform under cyclic conditions without failing. This makes it suitable for high-speed applications such as printing and milling. The only problem with using polyurethanes in high-speed conditions is their low heat dissipation, especially for thicker roller linings. High heat can eventually accelerate creep; this weakens the material.

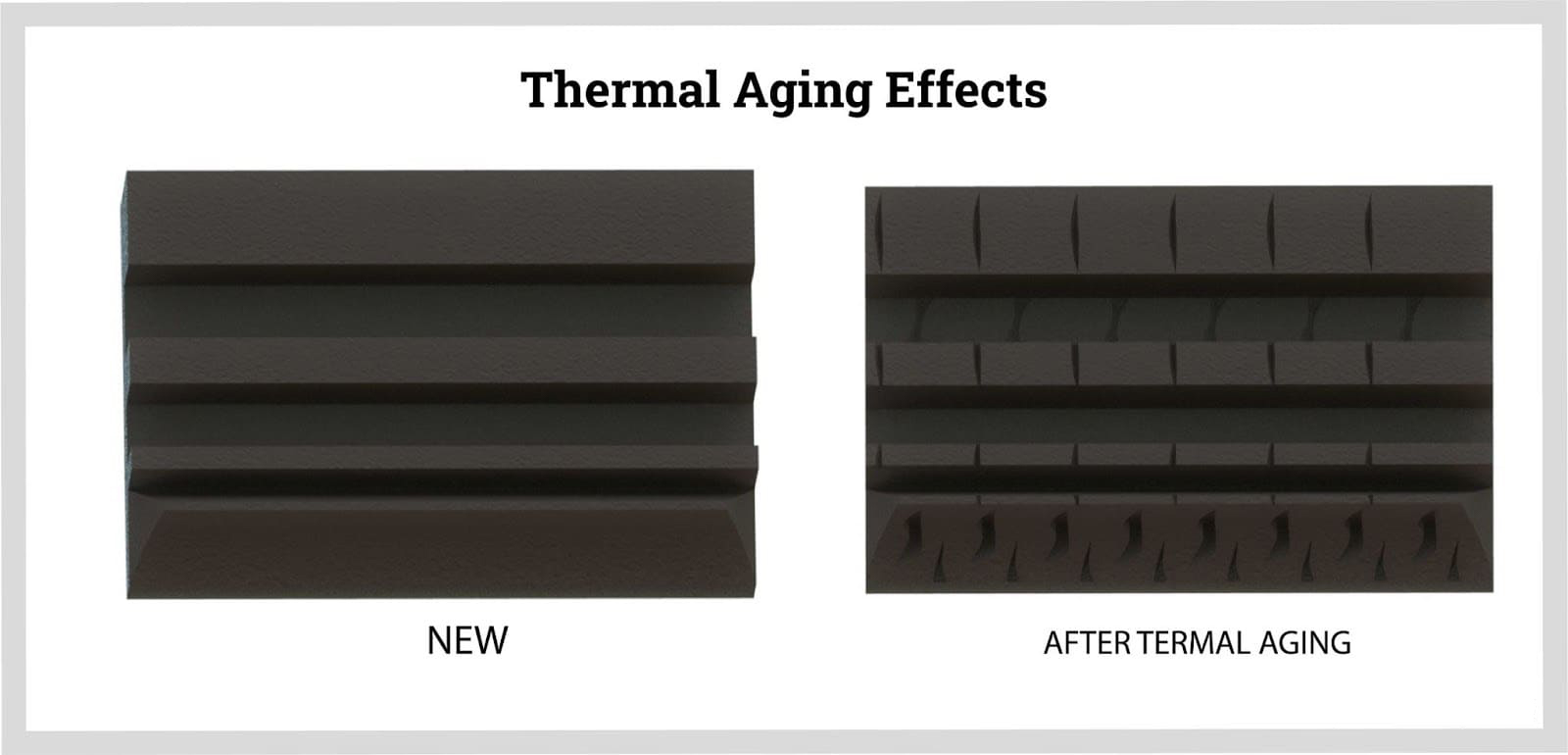

Thermal Aging Resistance

Thermal aging is the gradual degradation of elastomers under conditions of high temperature and an abundance of oxygen. It is characterized by a loss of strength and elasticity. This irreversible process creates operating temperature limits for the material.

Polyurethane exhibits good thermal aging resistance when formulated with certain compounds such as PPDI and CHDI. Typical polyurethanes have a maximum operating temperature of about 90 to 100 °F (32 to 38 °C). Special but more expensive formulations can reach 302 °F (150 °C).

Friction

Polyurethane‘s coefficient of friction (COF) correlates with its hardness. The two properties have an inverse relationship, meaning the COF increases while hardness decreases. Since the hardness of polyurethanes is easily manipulated through blending, the desired COF can also be attained.

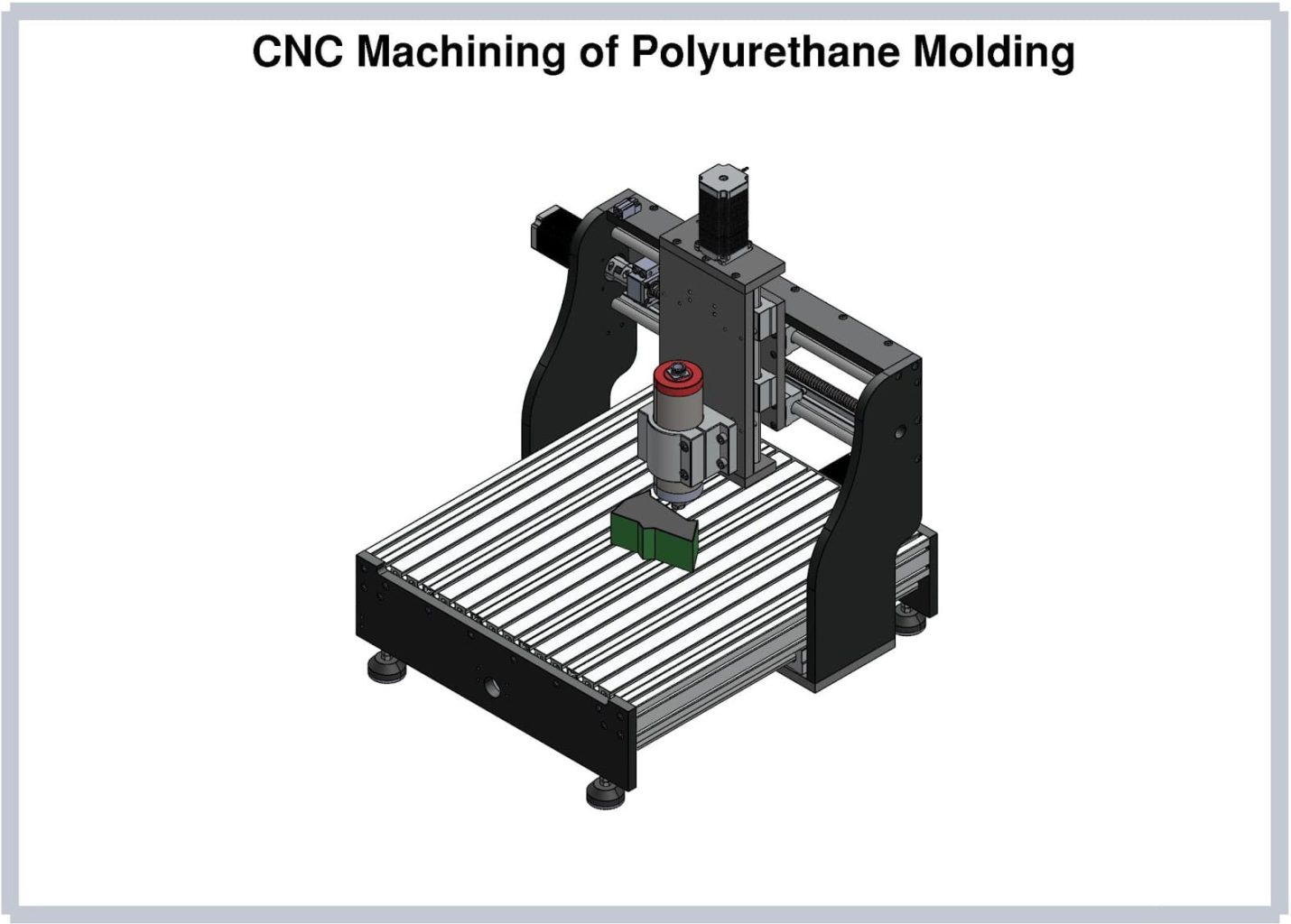

Machinability

Machinability is a property observed in hard polyurethanes. This property allows polyurethanes to be shaped into perfect geometries. This is particularly useful for finishing molded polyurethanes as it allows the product to be ground or lapped. These secondary processes remove imperfections on the surface of the product.

Chemical Resistance

The chemical resistance of polyurethanes depends on the type of polyol used in their polymer system. Ether-based systems are more resistant to water, making them suitable for wet applications. Ester-based, on the other hand, is best against oils, solvents, and most petroleum compounds.

Chapter 4: Molding Processes

Molding is the process of forming products by pouring or forcing molten or liquified material into a hard tool or mold. The mold is in the shape or profile of the finished product. In polyurethane molding, the processes are modified based on the form and fluid properties of the raw material and the geometry of the product being produced.

Polyurethane is an exceptionally flexible material that can be shaped, molded, formed, and produced in a wide variety of configurations to meet the needs of various industrial and commercial applications. It can be used repeatedly without concern for fractures, wear, or deterioration. Polyurethane is used for its many strengths, including its ability to withstand the effects of electricity and extreme temperatures.

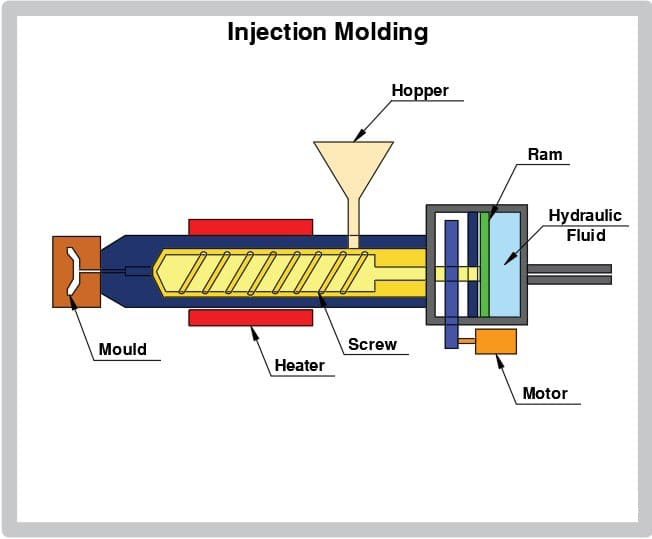

Injection Molding

Injection molding is the traditional process for creating polyurethane moldings. It is applicable for both thermoset and thermoplastic polyurethanes. This process involves heating and melting pelletized or powdered polyurethane to allow it to flow. A ram-type, reciprocating screw extruder then injects the molten polyurethane polymer system into a hard tool or mold. High pressures are used to force the polyurethane into the cavities and crevices of the mold. The mold is machined to a profile following the negative image of the finished product.

While inside the mold, the polyurethane starts to undergo curing. The curing phase transforms the liquid polyurethane into its final form. This is accomplished by applying heat or by allowing the curatives to react with the prepolymer system. In some processes, the heat carried by the molten polyurethane is enough to carry out the curing process. After curing, the molded polyurethane is cooled and released. The finished product can be solid, semi-solid, or cellular.

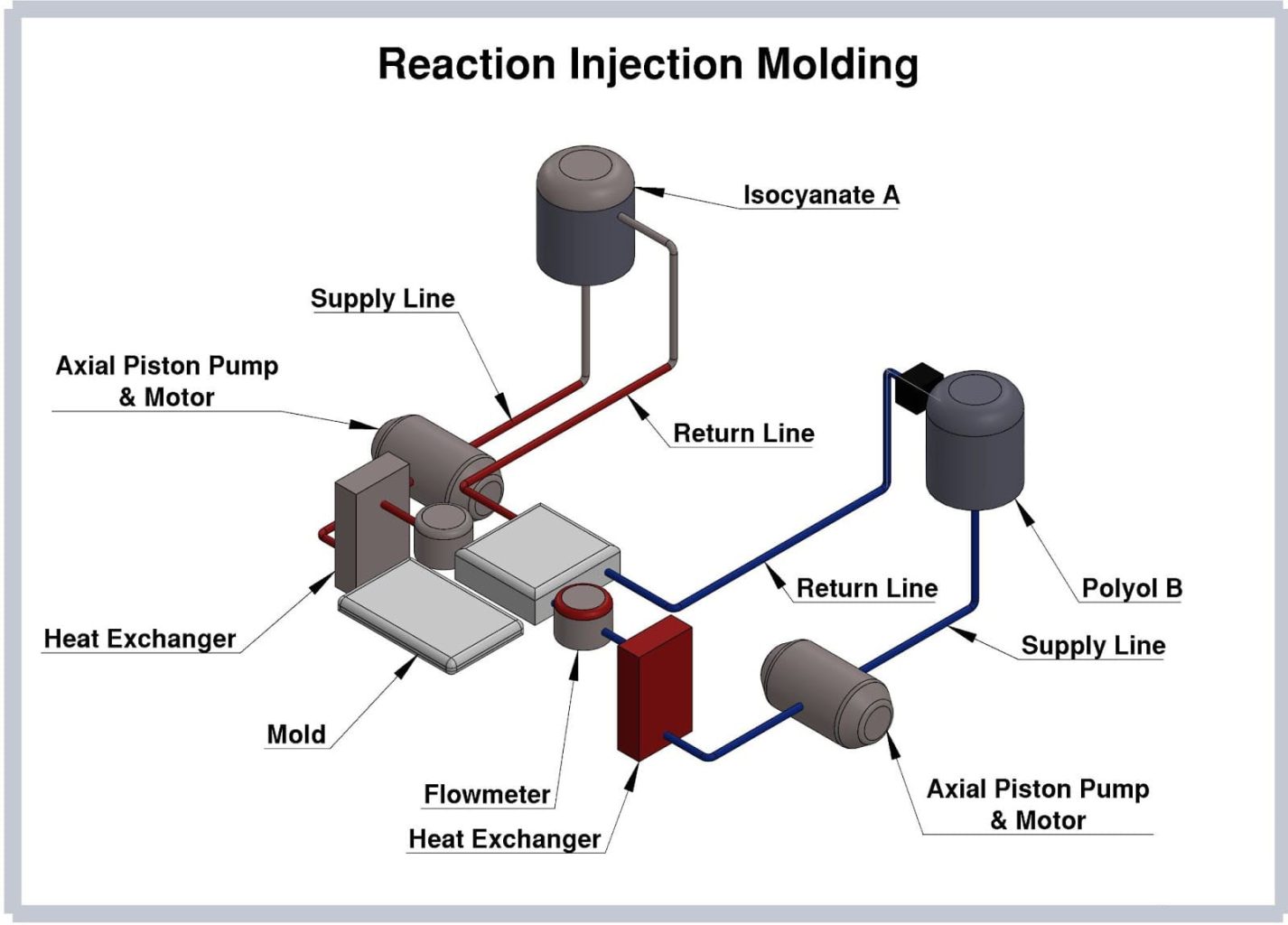

Reaction Injection Molding

This process is similar to injection molding. However, its main difference is the form of its raw materials. Reaction injection molding uses liquid prepolymer components, which are initially separated and contained in individual tanks. The components are then pumped into a mixing head, where they are blended. Immediately after the mixing head comes the mold, where the blended polymer is formed and cured. This process is limited to producing thermosetting polyurethanes.

This process eliminates the heating and melting of the polyurethane blend before injecting it into the mold. It only involves immediate mixing of the raw materials before molding. The liquid components used intrinsically have a low viscosity, making them easy to inject. This reduces tooling costs by allowing the use of less robust and expensive molds.

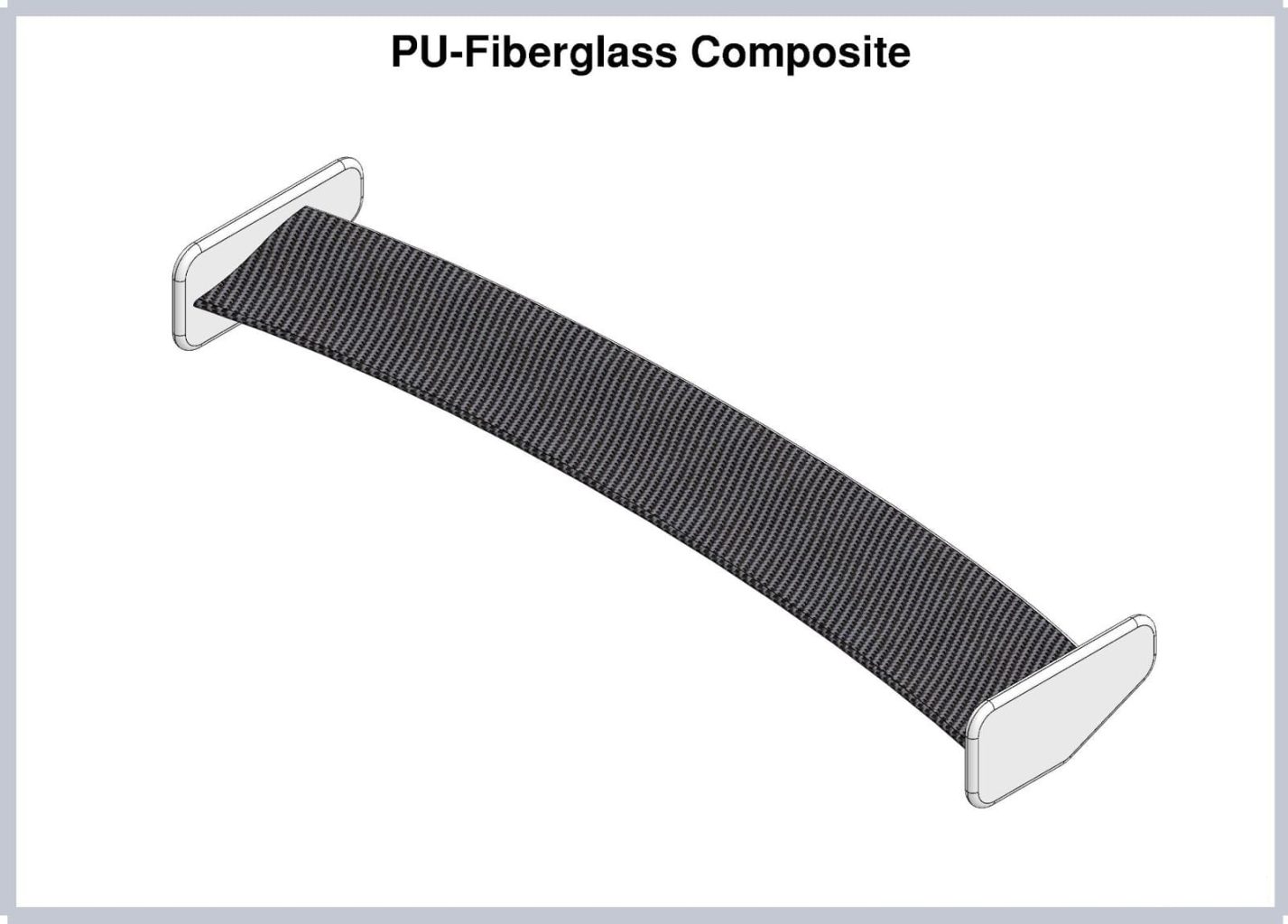

Several variations of reaction injection molding exist, such as reinforced reaction injection molding (RRIM) and structural reaction injection molding (SRIM). Both processes use reinforcing materials to strengthen the finished polyurethane molding. RRIM uses reinforcing agents such as fiberglass and carbon fiber. SRIM, on the other hand, uses fiber meshes.

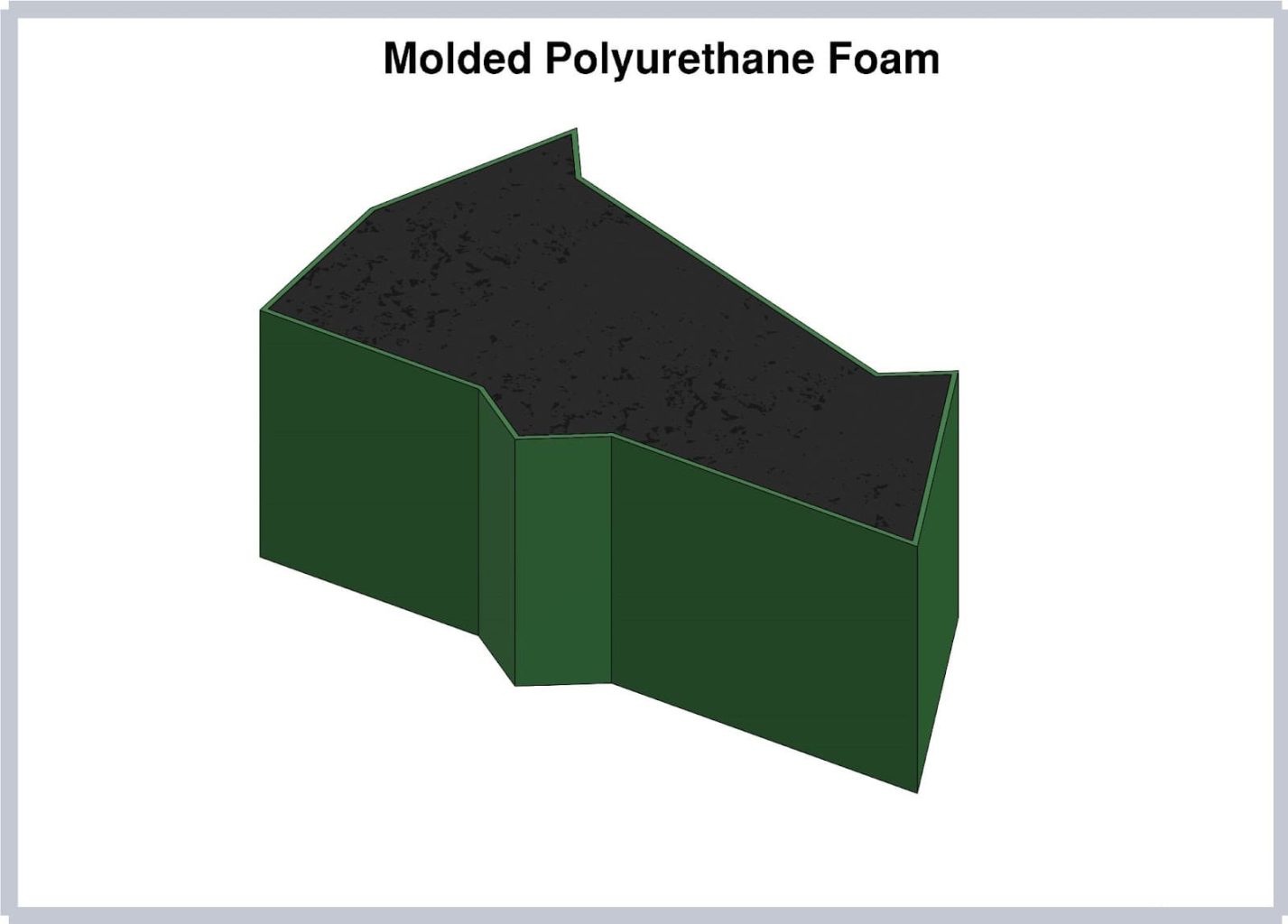

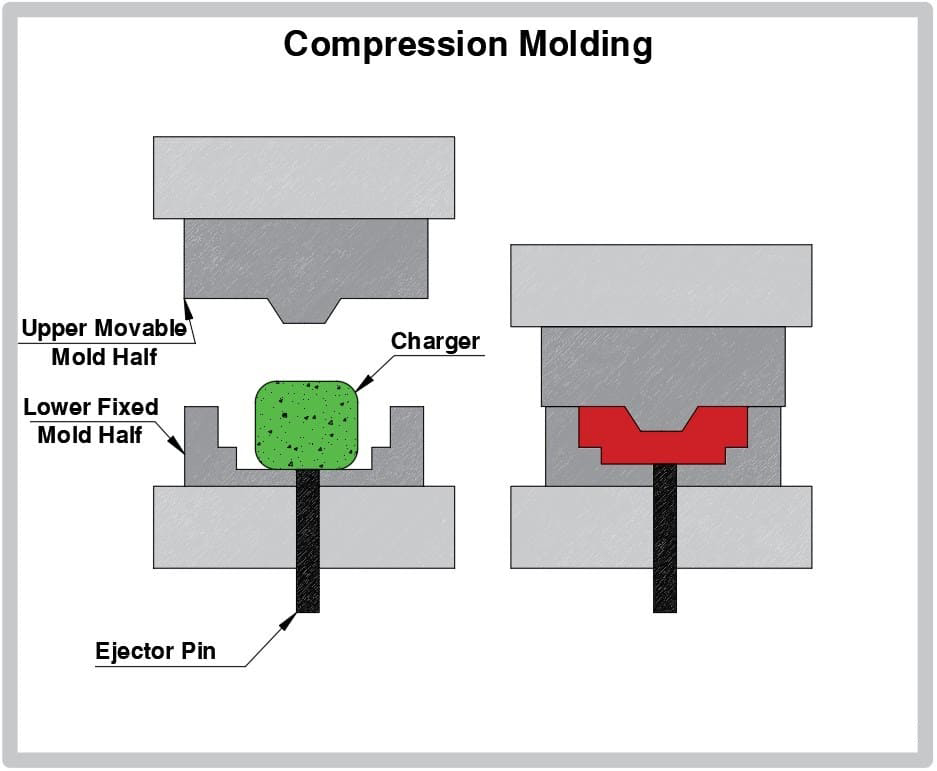

Compression Molding

Compression molding is a popular method for forming large thermosetting polyurethane products. This process uses a mold composed of an upper and lower half. The lower half receives a compounded polyurethane mass or charge with a predefined weight. The two halves of the mold are then compressed against each other to force the polymer mass to flow in the shape of the mold. The displaced gas is vented out of the mold to produce a homogenous product. After molding, the product is cured, cooled, and released from the mold.

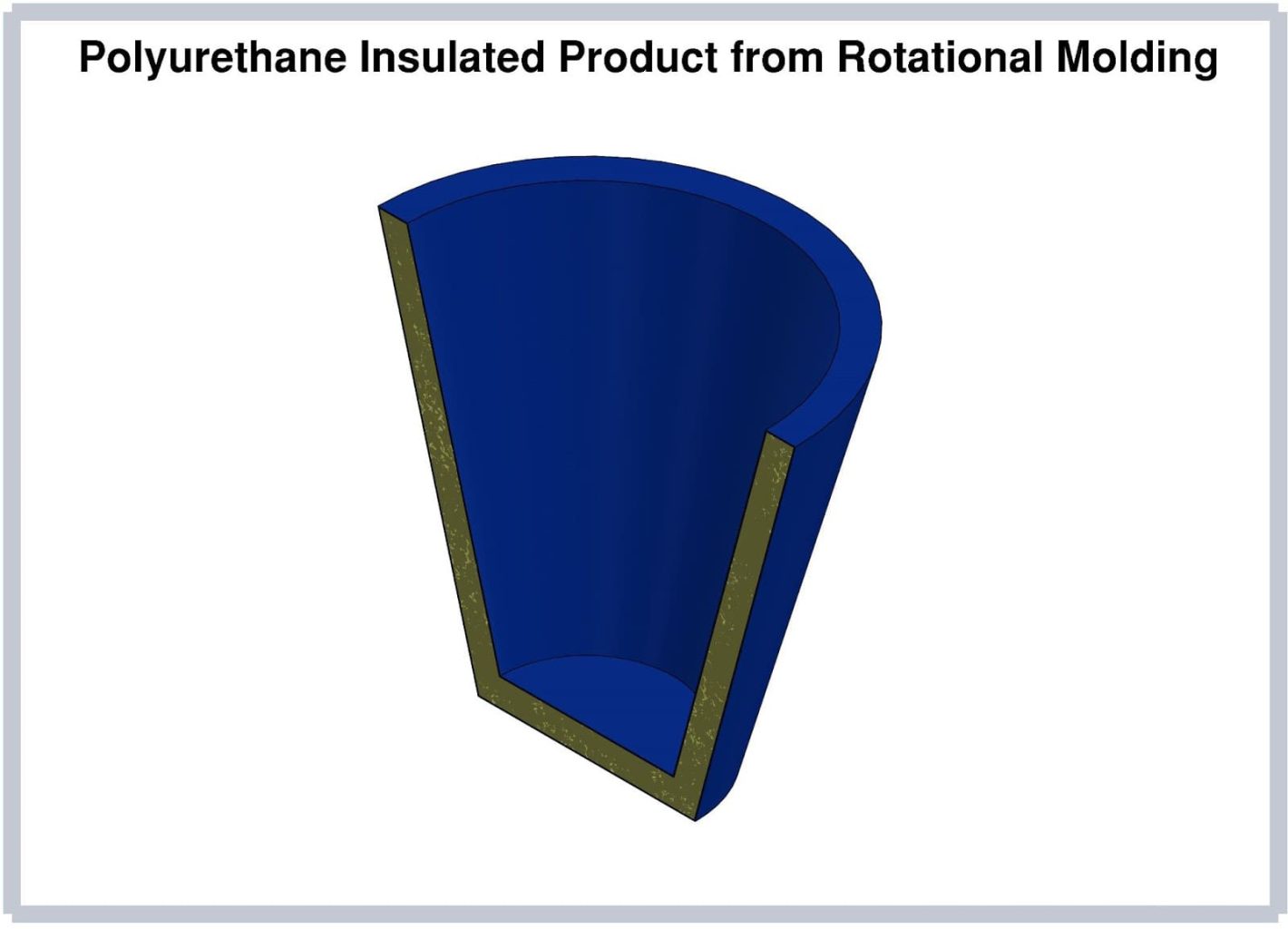

Rotational Molding

Rotational Molding is a process used to produce seamless, hollow products. This molding technique is done by loading powdered polyurethane into a mold. The mold is then heated while being rotated to melt the powdered polymer, so the material coats the inside surface of the mold. Unlike injection molding, this process does not use high pressure for injecting or extruding the polymer. Instead, it forms the container by spreading the plastic melt through rotation. After a predetermined number of rotations, the product is cooled and ejected from the mold.

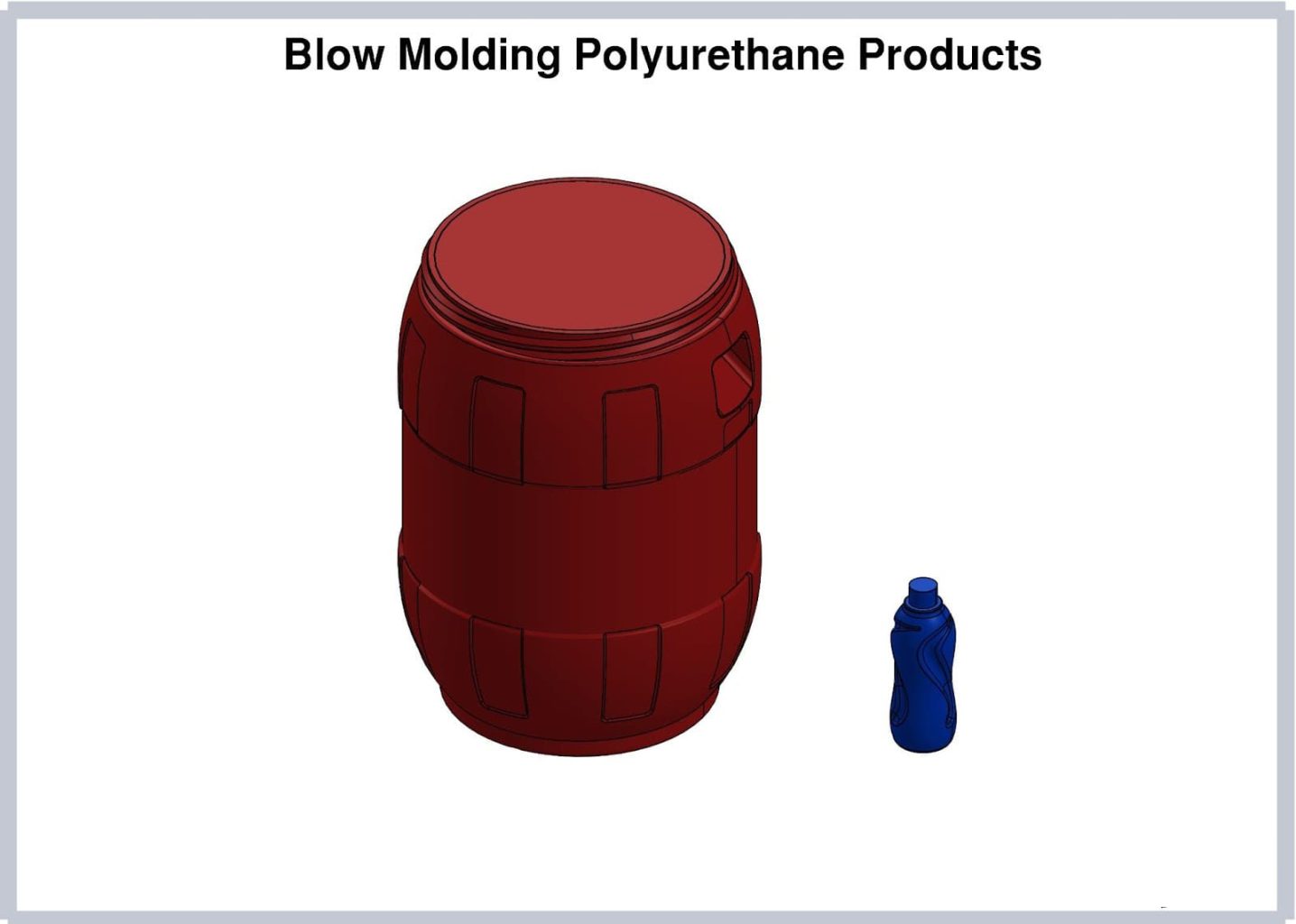

Blow Molding

Blow molding is the process of creating hollow products by inflating a softened preform inside a mold. It commonly uses thermoplastic polyurethanes as raw materials. This process involves heating the polyurethane and extruding it into a tube called a parison or preform. The preform is then enclosed and clamped inside a mold. Compressed air is then introduced on one end of the preform; this inflates the polyurethane to the shape of the mold. After molding, the product is allowed to cool and is later ejected from the mold.

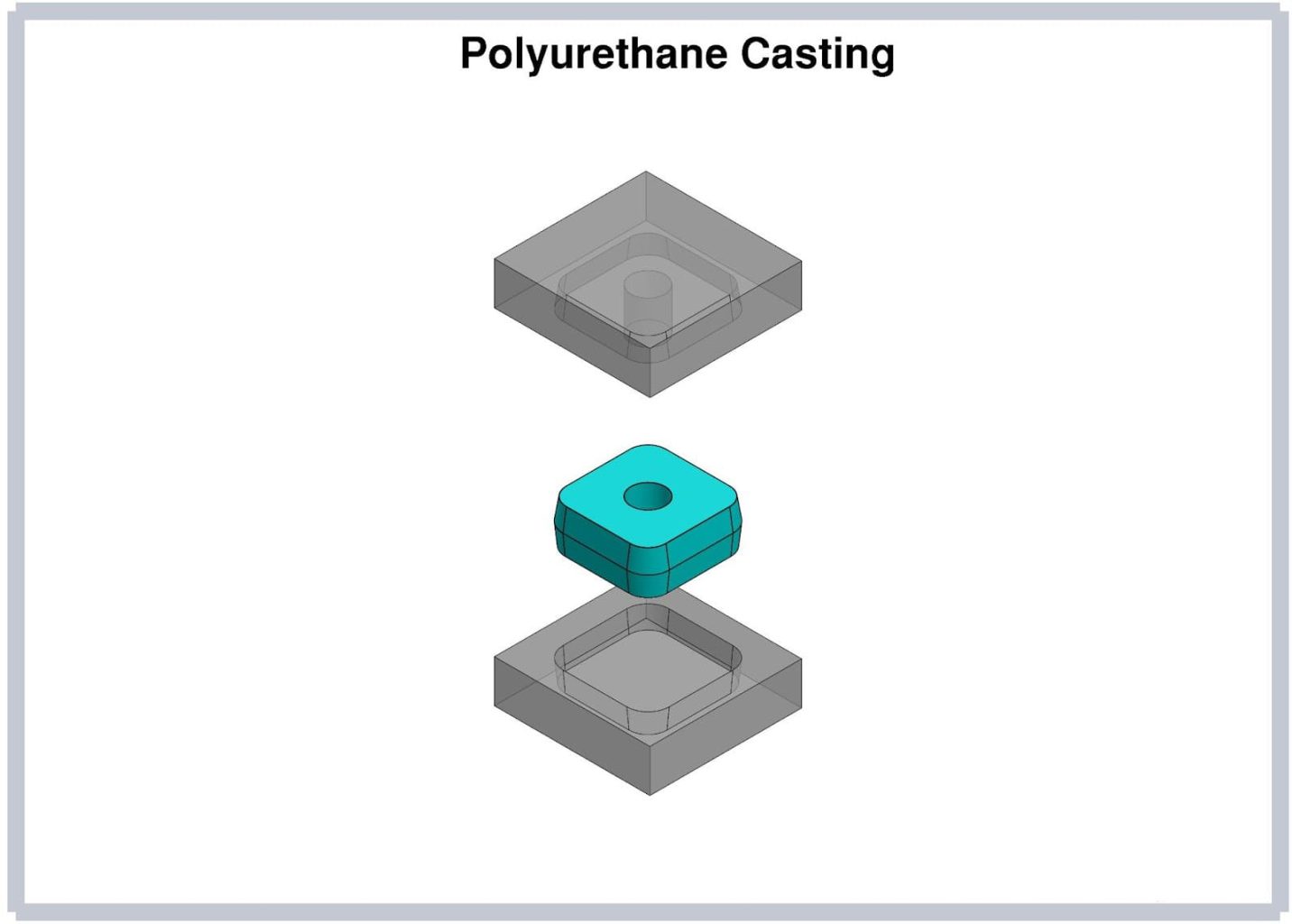

Casting

Urethane casting is the process of injecting polyurethane and additive resins into a soft mold usually made of silicone elastomer. The casting process is similar to injection molding; however, injection molding differs by the use of hard, metal molds. Urethane casting is usually applied on short-runs and low to medium-volume production. This is due to the quick wearing of the silicone mold. However, the preparation of the silicone mold is cheaper and faster than making a metal tool without sacrificing the final quality of the molded product.

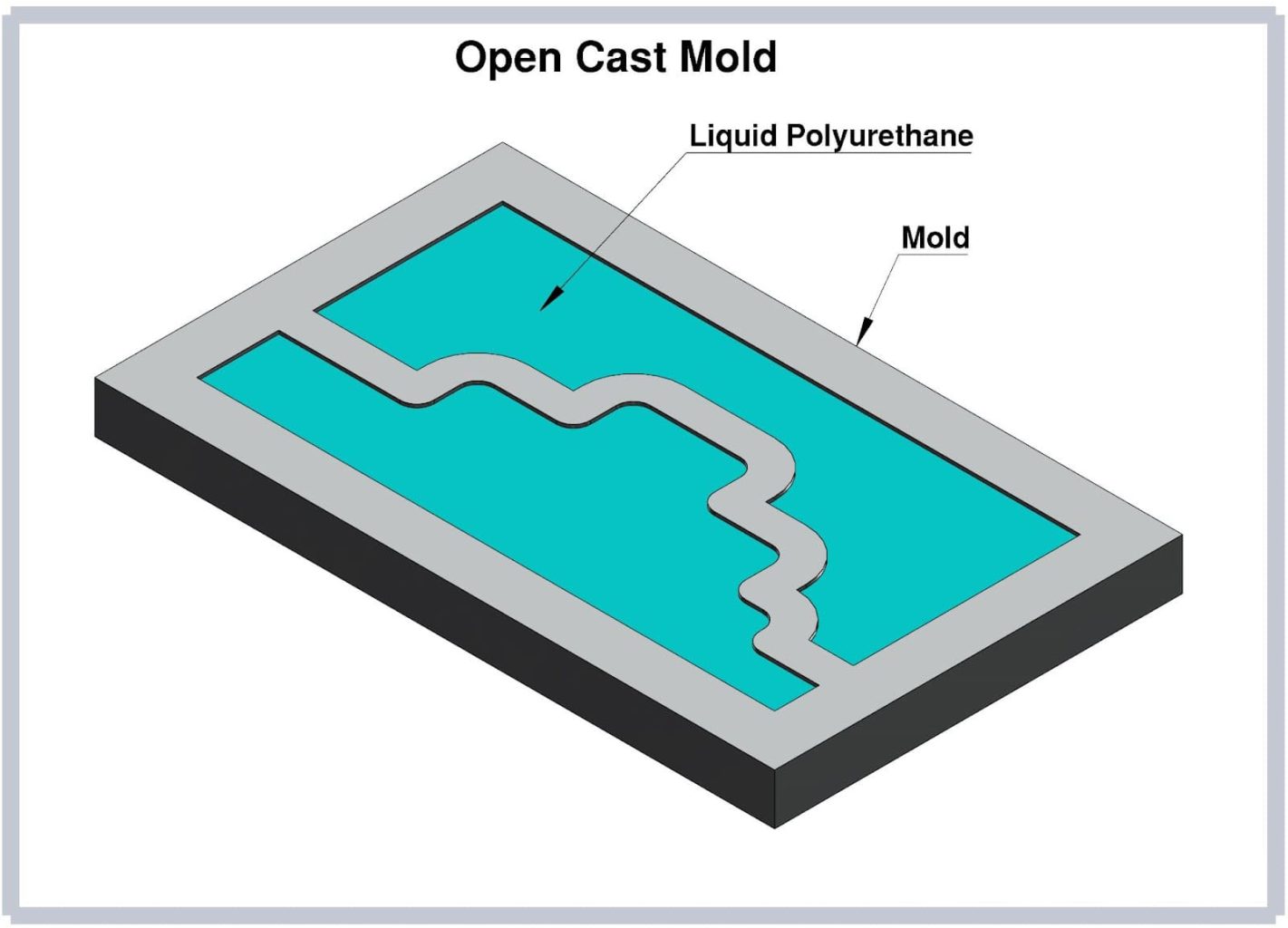

Open Cast Molding

Open cast molding is the simplest of the molding methods and is used for the manufacture of polyurethane products with high hardness in a variety of sizes. It is used when the number of required parts and the part design do not justify the use of the other molding methods. Open cast molding is quicker than other molding processes and can have completed products available in a few short weeks. The process involves pouring polyurethane into an open-top mold or having it flow up from the bottom of the mold.

As with other polyurethane molding methods, open cast molding begins with a liquid resin and curative that is heated to processing temperature. A key factor of open cast molding is ensuring the correct temperature of the resin and curative liquid, which has to be carefully and precisely weighed and mixed. During the mixing process, a chemical reaction occurs that initiates the change of the heated liquid to a solid.

While the mixture is still in liquid form, it is poured into molds that are heated to the same temperature as the resin and curative compound, which is about 220 °F (104 °C). Once placed in the mold, the polyurethane material quickly sets and is removed from the mold.

The benefits of open cast molding include:

- Materials – There are no limitations to the types of polymers that can be cast using open cast molding.

- Short Runs – Open cast molding is ideal for short production runs where setting up and machining for other polyurethane methods is too costly.

- Additives – The mixing of resins and curatives for open cast molding is completed by hand, which avoids the problems associated with mixing machines or batch tanks where additives can clog equipment.

Chapter 5: Raw Materials in Polyurethane

Polyurethanes are composed of different components. The main components are polyols and diisocyanates. Other components are the curatives and additives that give some of the unique properties of a specific polyurethane polymer formulation. Another set of components particular to polyurethane foams is blowing agents, surfactants, and catalysts, all of which aid in generating gases for creating the structure of the foam.

Prepolymer System

The polyurethane prepolymer system is made from two components: polyols and diisocyanates. These compounds react and form the polymer backbone of polyurethane. These two components are common to all types, whether they be castings, moldings, elastomers, coatings, or foams.

Polyol

A polyol is an organic molecule containing one or more hydroxyl (OH) groups. Polyols used in urethane casting are either polyether or polyester types.

Polyether

These are made by the reaction of organic oxides and glycol. Polyether is characterized by having good resilience, high impact resistance, low heat build-up for dynamic applications, hydrolysis resistance, and good low-temperature performance. Common types of polyether used in the polyurethane industry are PTMEG and PPG. Of the two, PTMEG offers superior quality but is more expensive.

Polyester

These are made by the polycondensation reaction of diacids and glycol. Compared to polyether, polyesters have good abrasion resistance, heat aging resistance, oil resistance, solvent resistance, good shock absorption properties, and better tear resistance.

Specialty Polyols

The most common are polycarbonate and polycaprolactone polyols. These two polyols are also sometimes classified as polyesters. Polycarbonates are used as engineering materials due to their strength and toughness. Polycaprolactone, on the other hand, gives cast urethane good water, oil, solvent, and chlorine resistance.

Diisocyanate

Like polyols, diisocyanate compounds form the resin side of the polyurethane system. There are two main types of diisocyanate: aliphatic and aromatic.

Aliphatic Diisocyanates

This type‘s most popular characteristic is its non-yellowing appearance. Also, they have lower reactivity, which makes them useful for chemical-resistant coatings. Aliphatic diisocyanates are mostly used in polyurethane coatings, films, and castings where color stability is required. The most common ADIs are hexamethylene (HDI), hexamethylene (HMDI), and isophorone (IPDI).

Aromatic Diisocyanates

Aromatic diisocyanates represent more than 90% of total diisocyanate consumption. This type is further divided into NDI, TDI, and MDI.

Naphthalenic Diisocyanates (NDI)

This type is more extensively used in Europe than in the TDI and MDI-dominated American market. NDIs are known to offer superior performance and long service life for dynamic applications. One downside of using NDIs is their high melting point, which makes them difficult to process. Moreover, they are highly reactive; this results in lower storage stability. Thus, they are usually manufactured with special equipment at the custom molder.

Toluene Diisocyanate (TDI)

In contrast to MDIs, this type is popularly used for high-hardness applications such as guide rollers. Typical forms of TDIs used on an industrial scale are the 2,4 and 2,6 isomers at an 80/20 blend. Producing proportions other than 80/20 requires an additional process.

Methylene Diphenyl Diisocyanate (MDI)

MDIs are known for imparting high resilience and impact strength to urethane casts. That is why MDIs, paired with either polyethers or polyesters, are used in dynamic, high impingement applications such as wheels, construction panels, automotive bumpers, and the like. The most common isomer used in casting is purified 4,4 isomers.

Polyurethane Foam Components

These are components unique to polyurethane foams. For the prepolymer system, in addition to polyols and diisocyanates, blowing agents, surfactants, and in some blends catalysts are essential components for making polyurethane foams. These additional raw materials generate foaming gases and control them to acquire the right foam structure.

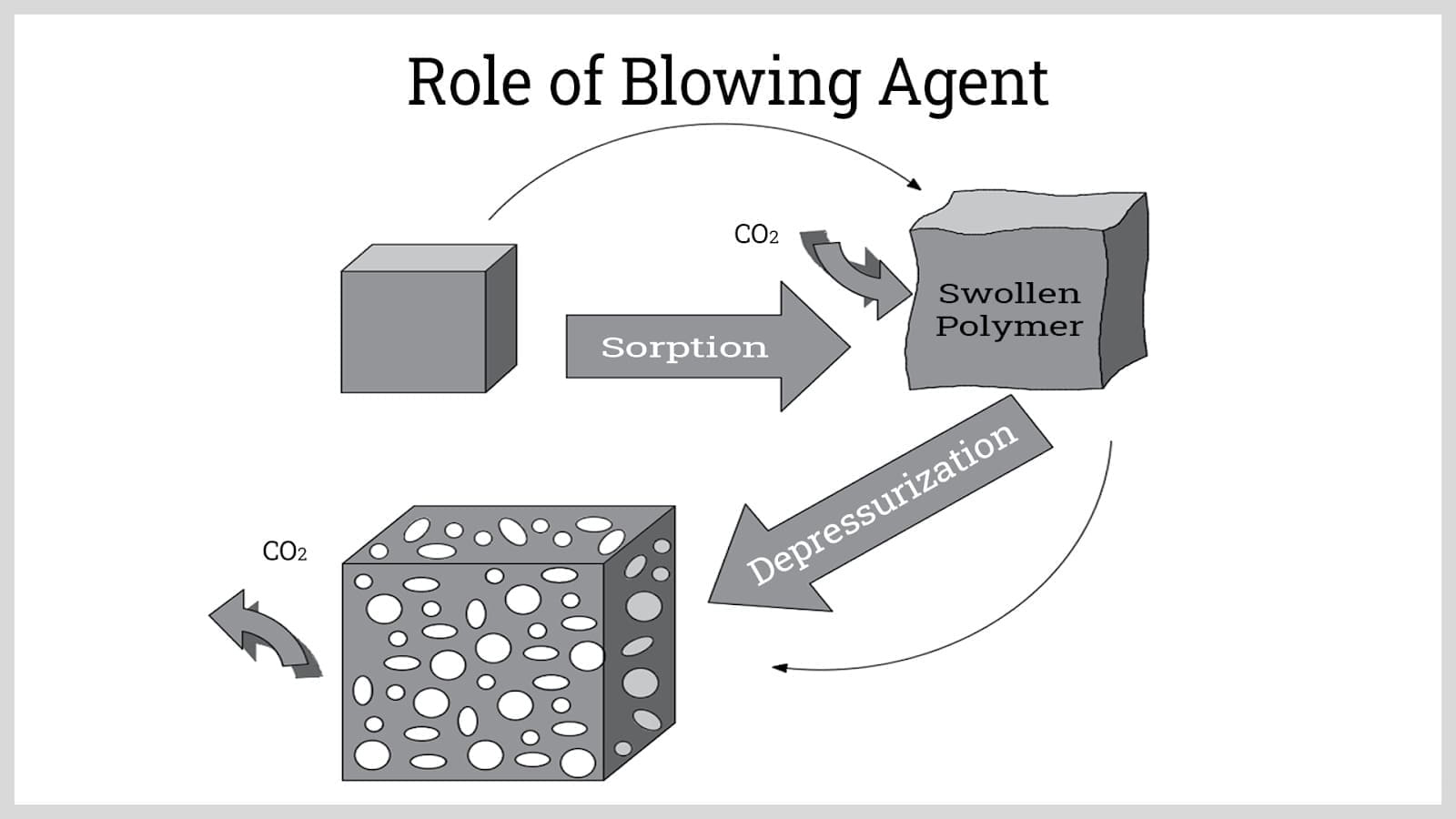

Blowing Agents

Blowing agents are used to generate gas to produce the foam‘s cellular structure. Gas can be introduced into the polymer system through chemical and physical means. The first blowing agent used was CFC-11, or trichlorofluoromethane. This was considered an ideal blowing agent due to its non-combustibility, appropriate boiling point, good compatibility with polyurethane, and non-toxicity. However, the chemical, along with other hydrochlorofluorocarbons, was banned through the Montreal Protocol in 1987 because it tends to cause ozone layer depletion. Today, CFCs are now being replaced by water, pentane, methylene chloride hydrocarbons, halogen-free azeotropes, and other zero ozone depletion-potential blends.

Chemical Blowing Agents

Chemical blowing agents generate gas by adding compounds that react with the isocyanate groups to form carbon dioxide gas. A common chemical blowing agent is water. Using water alone poses several problems, such as higher temperatures from the exothermic reaction, high polymer system viscosity, high consumption of isocyanates, and inefficient mixing. Thus, it is usually paired with a physical blowing agent. Other chemical blowing agents include enolizable organic compounds, polycarboxylic acid, and boric acid.

Physical Blowing Agents

Physical blowing agents, on the other hand, operate by vaporizing a volatile compound from the heat generated by the exothermic polymerization reaction. Since the ban on CFCs and HCFCs, new physical blowing agents have been developed, such as cyclopentane, n-pentanes, liquified CO2, methyl chloride hydrocarbons, and halogen-free azeotropes.

Surfactants

Surfactants are additives that help form, stabilize, and set polyurethane foams. The most widely used are silicone-based surfactants. Silicone surfactants perform important functions such as reducing surface tension, preventing foam collapse until cross-linking, controlling cell size, preventing cell shrinkage after cure, and counteracting any deformities induced by adding solids into the system.

Catalysts

Catalysts are used to control the rate of reaction of the isocyanate and hydroxyl groups and the rate of gas generation. These polymerization and gas generation processes usually need to occur simultaneously. If the polymerization process proceeds faster than the gas generation, the cells tend to remain close; this causes the foam to shrink as it cures and cools. Consequently, if the gas generation is faster, the cells expand before the polymer can cure and provide support. The rates of these two reactions must be balanced to produce uniform open cells.

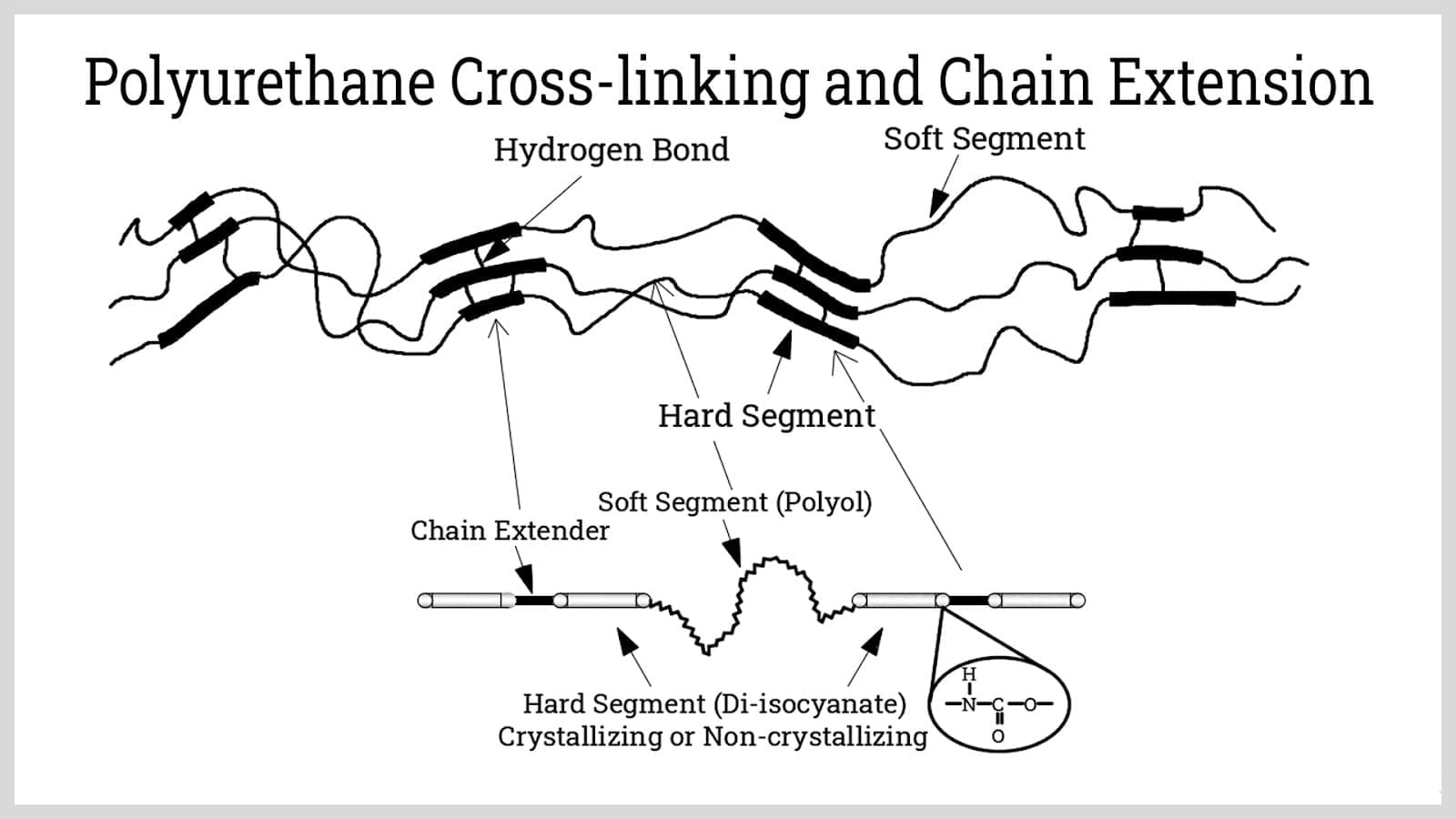

Curative and Chain Extenders

Curatives and chain extenders are used to cross-link the long, chained molecules formed by the reaction of the polyol and diisocyanate. They are mixed with the polyol and diisocyanate prepolymer system to form a solid or semi-solid elastomer. They are added in most thermosetting polyurethane formulations. There are two basic types: hydroxyls and amines.

Hydroxyls (Diols)

These curatives have hydroxyl groups (OH) at the molecule terminals that link prepolymers. The standard hydroxyl curative is 1,4-butanediol (BDO), commonly used in MDI prepolymer systems at room temperature.

Amines

Aside from hydroxyl groups, amine groups (NH2) can also bond on the terminals of the prepolymer. The widely used amine curative was 4,4-methylenebis (2-chloroaniline) or MOCA as the base curative for TDI prepolymer systems. However, this type was identified as a carcinogen by OSHA. Other amine chain extenders are now being used, such as 4,4-methylenebis (3-chloro-2,6-diethylaniline) (MCDEA).

Additives

Additives are used to give polyurethane products additional properties and characteristics. The type of additive and its amount is selected based on the formulation of the polymer system and the intended application. Some polyurethane additives are:

Fillers

Fillers are typically used to enhance the mechanical properties of the product. A less popular intention is to decrease the manufacturing cost by using less expensive raw materials without affecting the final characteristics of the product.

Plasticizers

Plasticizers increase the plasticity and fluidity of the polyurethane polymer. They act as processing aids that soften the polymer so that it can flow into molds and tools without the use of excessive heat and pressure.

Stabilizers

Stabilizer is a general term used to describe additives that prevent the degradation of the final polyurethane product. Common polyurethane degradation mechanisms include oxidation, thermal aging, and photo-oxidation. Stabilizer covers additives such as:

Antioxidants

For preventing reaction with oxygen and ozone.

Light or UV stabilizers

For preventing degradation through UV light.

Heat Stabilizers

For increasing the products‘ resistance to thermal degradation.

Biocides

For preventing degradation caused by microorganisms.

Antistatic Agents

Since this compound is added during the compounding of the polymer, these are specifically termed internal antistatic agents. These additives prevent the build-up of static electricity. Static electricity affects the material by altering its purity, moisture affinity, and surface properties.

Degassing Aids

Degassing is a process done in molding solid polyurethanes or for making polyurethane coatings and elastomers. Mixing the components of the polymer system tends to dissolve and trap gases; this may lead to a lower quality product. Degassing aids help remove these undesirable trapped gases.

Flame Retardants

These are substances added to polyurethanes to prevent them from combusting. Polyurethanes, especially polyurethane foams, are materials that can easily burn; this limits their potential functions. Flame retardant polyurethanes are used in automotive parts and building insulations.

Pigments and Colorants

Pigments and colorants are used to modify the appearance of the product. They give the final color of the polyurethane without affecting its mechanical and thermal properties.

Coefficient of Friction (COF)

COF additives are designed to raise or lower the coefficient of friction of a polyurethane product where a high COF is ideal for applications where there is sliding between surfaces. A lower COF increases the friction between materials and is found in harder polyurethane products. The COF of polyurethane is easily adjusted by changing the additive formulation.

Conclusion

- Polyurethane molding is the process of fabricating or manufacturing plastic parts by introducing a urethane polymer system into a tool or mold and allowing it to cure.

- Polyurethanes are extremely versatile materials that can have various formulations to yield different plastic properties. Their mechanical properties can vary from soft and pliable to hard and rigid.

- Polyurethane materials can be engineered to have different mechanical and chemical properties by formulating the polymer system with different components that are blended in specific quantities.

- Polyurethane molding processes include injection molding, reaction injection molding, compression molding, rotational molding, blow molding, and casting.

- Polyurethanes are made from polyols, diisocyanates, curatives, and additives. Additional components such as blowing agents, surfactants, and catalysts are included for making polyurethane foams.