Description

|

product name

|

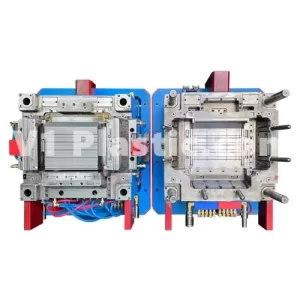

Injection molded plastic car radiator cooling fan cover shield mold

|

| Cavity and Core |

P20H、718H、2738H、S136、H13等。

|

| Material |

PP、HDPE、LDPE, PBT。

|

| mold base |

LKM,ISM,HASCO,DME

|

|

Cavity

|

Single/Multi cavity

|

| mold lifespan |

500,000 ~ 100,000,000 Pics

|

| Runner type | Cold/ hot runners |

| delivery time |

30 ~ 60day

|

Manufacturing, design, customization, automotive molds, precision injection molding, plastic models, automotive fan blade molds

There are many factors that affect the structure and mold system of injection molds, mainly including the following aspects:

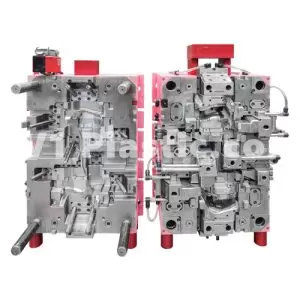

1. Layout of cavities. The number and arrangement of cavities should be determined based on the geometric structure of the plastic parts, dimensional accuracy requirements, batch size, difficulty of mold manufacturing, mold cost, etc.

2. Determine the parting surface. The position of the parting surface should be conducive to mold processing, exhaust demolding, and molding operations to ensure the surface quality of plastic parts.

3. Determine the pouring system (shape, position, and size of the main channel, runner, and gate) and exhaust system (method of exhaust, position and size of the exhaust groove).

4. Choose the ejection method (ejector pin, ejector pin, push plate, combination ejection), and determine the side concave treatment method and core pulling method.

5. Determine the cooling and heating methods, the shape and position of the heating and cooling tanks, and the installation position of the heating elements.

6. Determine the thickness, overall size, overall structure, and position of all connecting, positioning, and guiding parts of the mold parts based on the injection mold material, strength calculation, or empirical data.

7. Determine the structural form of the main molded parts and structural components.

8. Consider the strength of each part of the mold and calculate the working dimensions of the formed parts.